Addressing Airborne Contaminants with Extractive Explosion-Proof Local Ventilators: A Comprehensive Guide

2025-08-04

Addressing Airborne Contaminants with Extractive Explosion-Proof Local Ventilators

Table of Contents

1. Introduction to Airborne Contaminants in Mining

2. The Importance of Local Ventilation Systems

3. Understanding Extractive Explosion-Proof Local Ventilators

4. Key Design Features of Explosion-Proof Ventilators

5. Benefits of Using Extractive Local Ventilation

6. Install

Addressing Airborne Contaminants with Extractive Explosion-Proof Local Ventilators

Table of Contents

- 1. Introduction to Airborne Contaminants in Mining

- 2. The Importance of Local Ventilation Systems

- 3. Understanding Extractive Explosion-Proof Local Ventilators

- 4. Key Design Features of Explosion-Proof Ventilators

- 5. Benefits of Using Extractive Local Ventilation

- 6. Installation Considerations for Effective Ventilation

- 7. Maintenance and Operation Best Practices

- 8. Case Studies of Successful Implementation

- 9. Frequently Asked Questions

- 10. Conclusion and Future Outlook

1. Introduction to Airborne Contaminants in Mining

Airborne contaminants pose significant risks in coal mining and other metallurgical operations. These contaminants, including dust, gases, and volatile organic compounds (VOCs), can adversely impact workers' health and safety. Effective ventilation systems are crucial to minimizing these hazards. Extractive explosion-proof local ventilators have emerged as a pivotal solution for addressing these airborne contaminants while ensuring compliance with safety regulations.

2. The Importance of Local Ventilation Systems

Local ventilation systems are designed to control and reduce airborne pollutants in specific areas where they are generated. Unlike general ventilation systems, which may dilute contaminants throughout a larger area, local ventilation systems target the source of pollution, effectively capturing and exhausting harmful substances before they can spread. This targeted approach is particularly vital in underground coal mines, where confined spaces exacerbate the accumulation of hazardous materials.

3. Understanding Extractive Explosion-Proof Local Ventilators

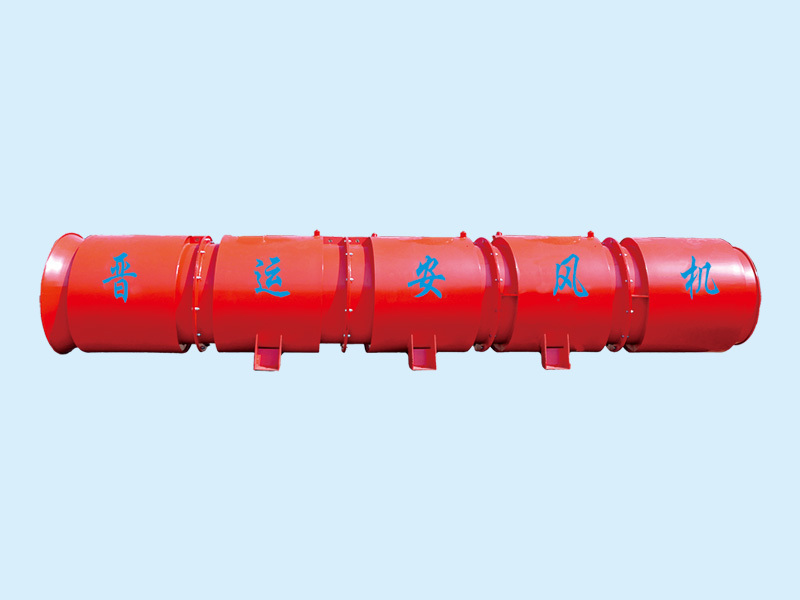

Extractive explosion-proof local ventilators are specialized devices engineered to operate in environments with explosive atmospheres. These ventilators extract contaminated air directly from the source, preventing the build-up of flammable gases and dust. The "explosion-proof" designation indicates that the design can withstand internal explosions without causing ignition in the surrounding environment, a critical feature in underground mining operations where methane and coal dust are prevalent.

3.1 How They Work

These ventilators typically consist of a motor, fan, and a series of filters. The system operates by pulling contaminated air through the filters, which capture particulates and harmful gases. The purified air is then expelled safely outside the working area. This process not only improves air quality but also mitigates the risk of explosion and fire.

4. Key Design Features of Explosion-Proof Ventilators

When choosing extractive explosion-proof local ventilators, various design features should be considered:

4.1 Robust Construction

The construction materials must be durable and resistant to corrosion, heat, and chemical exposure. This ensures longevity and reliability in harsh mining conditions.

4.2 Advanced Filtration Systems

High-efficiency particulate air (HEPA) filters and activated carbon filters can significantly enhance the air purification process, ensuring that even the smallest contaminants are removed.

4.3 Variable Speed Control

Ventilators equipped with variable speed controls allow for adjustments based on real-time air quality measurements, providing optimized airflow depending on the level of contamination.

4.4 Safety Features

Integrated safety measures, such as pressure relief valves and explosion-proof enclosures, are essential to protecting both the equipment and personnel in high-risk environments.

5. Benefits of Using Extractive Local Ventilation

The advantages of employing extractive explosion-proof local ventilators in mining operations are manifold:

5.1 Improved Worker Safety

By effectively removing harmful airborne contaminants, these ventilators enhance the overall safety of miners, reducing the risk of respiratory diseases and other health issues associated with poor air quality.

5.2 Regulatory Compliance

Mining operations must adhere to strict safety regulations regarding air quality. Implementing local ventilation systems helps companies meet these requirements, avoiding costly fines and legal issues.

5.3 Increased Operational Efficiency

With cleaner air, workers can perform their tasks more efficiently. Improved air quality directly correlates with enhanced productivity and reduced downtime due to health-related absences.

5.4 Environmental Protection

Extractive ventilators also contribute positively to the environment by minimizing the release of pollutants into the atmosphere, aligning mining operations with sustainable practices.

6. Installation Considerations for Effective Ventilation

The successful installation of extractive explosion-proof local ventilators requires careful planning and execution:

6.1 Site Assessment

A thorough site assessment is essential to identify areas with the highest concentrations of airborne contaminants. This assessment should include evaluating air flow patterns and potential sources of pollution.

6.2 Equipment Placement

Strategically placing ventilators near the source of contamination maximizes their efficiency. The distance from the pollution source and the layout of the working area are critical factors to consider.

6.3 Integration with Existing Systems

If an existing ventilation system is in place, integrating the new ventilators into that system may enhance overall performance. Collaborating with HVAC professionals can ensure a seamless integration process.

7. Maintenance and Operation Best Practices

To ensure longevity and optimal performance, regular maintenance of extractive explosion-proof local ventilators is paramount:

7.1 Routine Inspections

Conducting routine inspections helps identify wear and tear before they become severe issues. Maintenance personnel should check electrical components, fan operation, and filter conditions regularly.

7.2 Filter Replacement

Filters should be replaced in accordance with manufacturers’ recommendations or when performance drops. Clogged filters can hinder airflow and reduce system efficiency.

7.3 Training Personnel

Training personnel on the operation and maintenance of ventilation systems is critical. Ensuring that staff understands how to identify issues and perform basic troubleshooting enhances system reliability.

8. Case Studies of Successful Implementation

Several mining operations have successfully integrated extractive explosion-proof local ventilators, achieving significant improvements in air quality and worker safety:

8.1 Case Study 1: XYZ Coal Mine

At XYZ Coal Mine, the installation of extractive local ventilators reduced airborne dust levels by over 50%, leading to a marked decrease in respiratory illnesses among miners.

8.2 Case Study 2: ABC Metallurgical Facility

ABC Metallurgical Facility implemented a comprehensive ventilation strategy that included extractive ventilators, resulting in compliance with environmental regulations and increased operational efficiency.

9. Frequently Asked Questions

9.1 What are extractive explosion-proof local ventilators?

Extractive explosion-proof local ventilators are specialized systems designed to remove airborne contaminants in explosive environments, ensuring safety and compliance.

9.2 How do these ventilators improve worker safety?

By capturing and removing harmful pollutants at their source, these ventilators significantly reduce the risk of respiratory issues and other health hazards for workers.

9.3 What maintenance is required for these systems?

Regular inspections, filter replacements, and personnel training are essential to maintaining the efficiency and reliability of extractive ventilators.

9.4 Can extractive ventilators be integrated with existing ventilation systems?

Yes, they can be integrated with existing systems to enhance overall performance, provided a thorough evaluation is conducted.

9.5 What are the key benefits of using extractive local ventilation?

The primary benefits include improved air quality, enhanced worker safety, regulatory compliance, increased operational efficiency, and reduced environmental impact.

10. Conclusion and Future Outlook

The implementation of extractive explosion-proof local ventilators represents a significant advancement in managing airborne contaminants in the mining and metallurgical sectors. By focusing on worker safety, regulatory compliance, and operational efficiency, these systems play a crucial role in modern mining practices. As technology continues to evolve, we can expect further innovations in ventilation systems, leading to even safer and more sustainable mining operations. Investing in robust local ventilation solutions is not merely a compliance measure—it is a commitment to the health and safety of workers and the environment.

Keywords:

Related News

Addressing Airborne Contaminants with Extractive Explosion-Proof Local Ventilators

Table of Contents

1. Introduction to Airborne Contaminants in Mining

2. The Importance of Local Ventilation Systems

3. Understanding Extractive Explosion-Proof Local Ventilators

4. Key Design Features of Explosion-Proof Ventilators

5. Benefits of Using Extractive Local Ventilation

6. Install

04 Aug,2025

Ensuring Safety: The Role of Flameproof Push-in Axial Flow Fans in Coal Mines

Ensuring Safety: The Role of Flameproof Push-in Axial Flow Fans in Coal Mines

Table of Contents

1. Introduction to Flameproof Push-in Axial Flow Fans

2. The Importance of Safety in Coal Mining

3. Key Design Features of Flameproof Push-in Axial Flow Fans

4. How Flameproof Push-in Axial Flow Fans Work

5. Benefits of Using Flameproof Fans in Coal Mines

6. Case Studies: Succes

29 Jul,2025

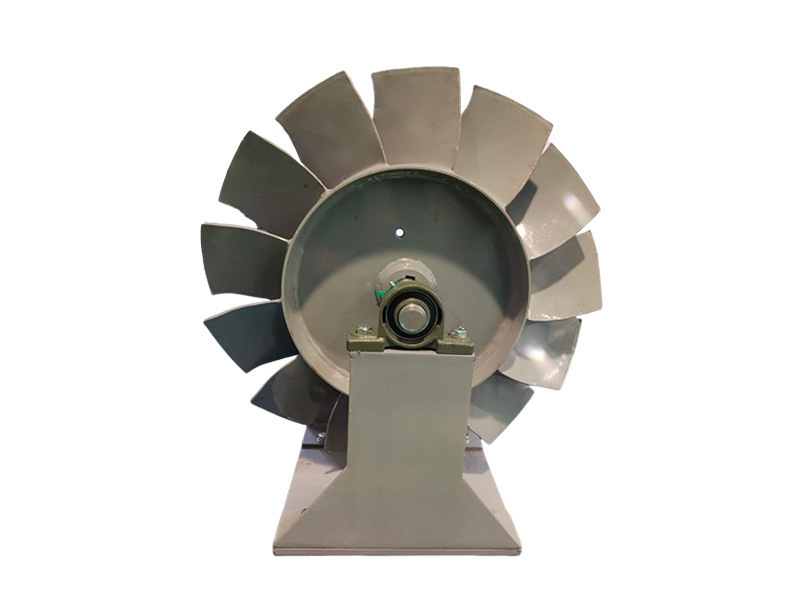

Advanced Negative Pressure Local Fan

The Advanced Negative Pressure Local Fan is engineered to deliver superior ventilation performance by efficiently extracting dust, fumes, and airborne contaminants directly at their source.

28 Jul,2025