Ensuring Safety in Mining: A Comprehensive Guide to Extractive Explosion-Proof Local Ventilators

2025-09-15

Ensuring Safety in Mining: A Comprehensive Guide to Extractive Explosion-Proof Local Ventilators

Table of Contents

Introduction to Mining Safety and Ventilation

The Importance of Ventilation in Mining Operations

Key Safety Regulations for Mining Ventilation Systems

Understanding Extractive Explosion-Proof Local Ventilators

Design Considerations for Explosion-Proof Ventilat

Ensuring Safety in Mining: A Comprehensive Guide to Extractive Explosion-Proof Local Ventilators

Table of Contents

- Introduction to Mining Safety and Ventilation

- The Importance of Ventilation in Mining Operations

- Key Safety Regulations for Mining Ventilation Systems

- Understanding Extractive Explosion-Proof Local Ventilators

- Design Considerations for Explosion-Proof Ventilators

- Installation and Maintenance of Ventilation Systems

- Training Workers on Safety Regulations and Equipment Use

- Future Trends in Mining Ventilation Technology

- Frequently Asked Questions

- Conclusion

Introduction to Mining Safety and Ventilation

Mining is an essential industry that fuels various sectors including energy, construction, and manufacturing. However, it is also one of the most hazardous professions, with risks ranging from cave-ins to harmful gases. Ensuring **worker safety** is paramount, and effective ventilation plays a crucial role in achieving this. **Extractive explosion-proof local ventilators** are specialized equipment designed to mitigate risks associated with explosive gases and dust, ensuring a safer working environment for miners. This article delves into the intricate details of safety regulations and practices surrounding these vital systems.

The Importance of Ventilation in Mining Operations

Proper ventilation in mining operations is not merely a regulatory requirement; it is a fundamental aspect of **worker health and safety**. Adequate ventilation helps control the concentration of hazardous gases such as methane and carbon monoxide while also managing dust levels that can lead to respiratory issues. A well-designed ventilation system enhances mine efficiency and productivity by ensuring that workers can operate in a safer environment, reducing the likelihood of accidents.

Health Risks Associated with Poor Ventilation

Inadequate ventilation can lead to a range of health risks for miners. Prolonged exposure to harmful gases can result in serious health complications, including explosive gas ignition, respiratory diseases, and even fatalities. Dust accumulation can also lead to pneumoconiosis, commonly known as black lung disease, which severely affects miners' respiratory functions. Therefore, effective ventilation systems are indispensable for safeguarding the health and well-being of all personnel involved in mining operations.

Key Safety Regulations for Mining Ventilation Systems

Compliance with safety regulations is crucial for any mining operation. **Regulatory bodies** such as the Mine Safety and Health Administration (MSHA) in the United States outline specific standards for ventilation systems to protect miners. These regulations dictate the design, implementation, and maintenance of ventilation systems, with an emphasis on risk reduction.

Understanding Regulatory Standards

Mining companies must adhere to a range of safety standards, including:

- **Ventilation Plan Requirements:** Each mining operation must develop and submit a ventilation plan that outlines how air will circulate throughout the mine.

- **Air Quality Monitoring:** Regular monitoring of air quality is mandated to ensure that contaminant levels remain within acceptable limits.

- **Emergency Procedures:** Regulations require that mines have protocols in place for addressing air quality emergencies, including evacuation plans and immediate response measures.

- **Training Requirements:** Miners must be trained on the proper use of ventilation systems and emergency procedures, ensuring they are prepared to respond to potential hazards.

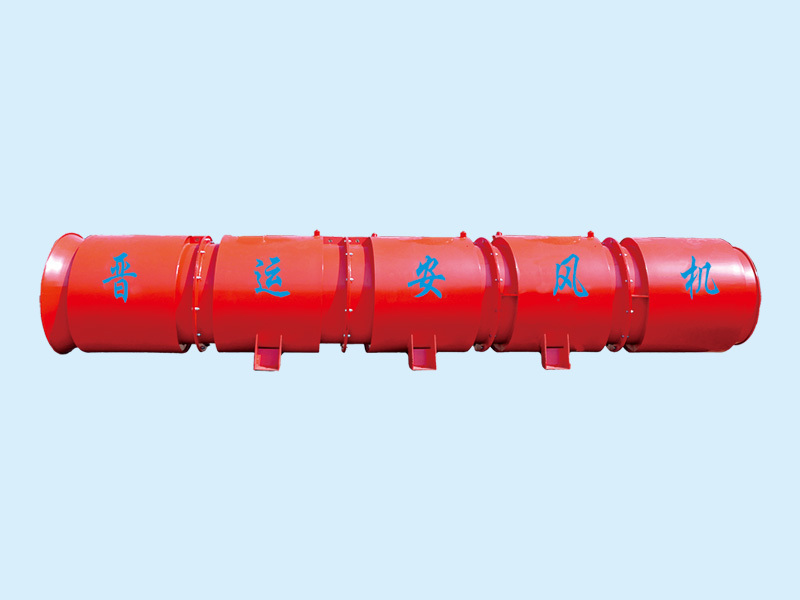

Understanding Extractive Explosion-Proof Local Ventilators

Extractive explosion-proof local ventilators are specialized devices designed to enhance ventilation in hazardous mining environments. Their primary function is to remove harmful gases and dust while preventing the ignition of flammable materials.

Key Features of Explosion-Proof Ventilators

These ventilators are engineered with several essential features:

- **Explosion-Proof Housing:** The casing is built to withstand explosions, minimizing the risk of ignition.

- **High-Efficiency Filters:** Advanced filtration systems remove particulates and gases from the air, ensuring cleaner air quality for miners.

- **Robust Fan Systems:** Powerful fans provide efficient air circulation, maintaining necessary air flow rates even in challenging conditions.

- **Automatic Control Systems:** Many modern units feature automatic controls that adjust airflow based on real-time environmental conditions, ensuring optimal performance.

Design Considerations for Explosion-Proof Ventilators

When designing explosion-proof local ventilators for mining operations, several factors must be considered to ensure effectiveness and compliance with safety regulations.

Site-Specific Requirements

Each mine presents unique challenges, including geological conditions, depth, and the types of minerals extracted. Therefore, ventilator design should be tailored to meet these specific conditions. Factors to be assessed include:

- **Depth of Mining Operations:** The deeper the mine, the more robust the ventilation system must be to combat high pressure and temperature.

- **Mineral Composition:** Different minerals release varying levels of gases, which must be accounted for in the ventilation design.

- **Volume of Airflow Required:** Calculating the necessary airflow to dilute and remove harmful gases is essential for maintaining safety.

Integration with Other Safety Systems

Explosion-proof ventilators should be integrated with other safety systems, such as gas detection and alarm systems. This integration ensures early detection of hazardous conditions, allowing for swift corrective action before accidents occur.

Installation and Maintenance of Ventilation Systems

The installation of explosion-proof local ventilators is critical to their performance and must be conducted by professionals who understand the specific challenges of mining environments.

Best Practices for Installation

- **Site Assessment:** Conduct a thorough site assessment to determine the best locations for ventilator installation.

- **Compliance with Regulations:** Ensure that installations meet all regulatory requirements and safety standards.

- **Testing and Commissioning:** Perform tests to verify that the system operates as intended before commencing full-scale operation.

Regular Maintenance Protocols

To ensure long-term reliability, regular maintenance of ventilation systems is essential. This includes:

- **Routine Inspections:** Frequent checks for wear and tear, ensuring all components function correctly.

- **Filter Replacement:** Timely replacement of filters to maintain air quality standards.

- **Performance Monitoring:** Continuously monitor the system's performance to detect any inefficiencies that may arise.

Training Workers on Safety Regulations and Equipment Use

Training is a vital component in ensuring the safe operation of extractive explosion-proof local ventilators. **Proper education on safety regulations** and equipment use enhances miners' ability to respond effectively to potential hazards.

Comprehensive Training Programs

Training should encompass:

- **Understanding Ventilation Systems:** Workers should be educated on how ventilation systems operate and their importance in maintaining a safe working environment.

- **Emergency Response Procedures:** Training should include emergency protocols for gas leaks, equipment failure, and evacuation procedures.

- **Regular Refreshers:** Conduct regular refresher courses to keep all personnel informed about updates in safety regulations and equipment technology.

Future Trends in Mining Ventilation Technology

The future of mining ventilation technology is promising, with innovations aimed at enhancing safety and efficiency.

Advancements in Smart Ventilation Systems

Emerging technologies such as **smart ventilation systems** utilize sensors and AI algorithms to optimize airflow dynamically. These advanced systems can predict gas concentrations and adjust ventilation accordingly, significantly improving safety outcomes.

Sustainability in Ventilation Design

As the industry moves towards sustainability, future ventilation systems will likely incorporate eco-friendly designs and energy-efficient technologies, reducing the environmental impact of mining operations while ensuring safety.

Frequently Asked Questions

1. What are the primary functions of extractive explosion-proof local ventilators?

Extractive explosion-proof local ventilators primarily remove harmful gases and dust from mining environments, ensuring a safer atmosphere for workers.

2. How often should ventilation systems be inspected?

Regular inspections should be conducted at least quarterly, with more frequent checks in areas with higher risks or following any significant changes in mining conditions.

3. What training is required for workers operating ventilation systems?

Workers must undergo comprehensive training on the operation of ventilation systems, emergency response procedures, and safety regulations to ensure they are prepared for potential hazards.

4. How can mining companies ensure compliance with safety regulations?

Mining companies can ensure compliance by maintaining up-to-date knowledge of regulations, implementing effective safety management systems, and conducting regular audits and training programs.

5. What are the latest trends in mining ventilation technology?

Recent trends include the adoption of smart ventilation systems that use sensors and AI for real-time monitoring and adjustments, as well as a focus on sustainability and energy efficiency.

Conclusion

In conclusion, the safety of miners is of utmost importance, and effective ventilation systems are essential in achieving this goal. By adhering to safety regulations, implementing advanced extractive explosion-proof local ventilators, and ensuring ongoing training, mining operations can create a safer working environment. As technology continues to evolve, the mining industry must remain vigilant and proactive in adopting innovative solutions to enhance safety and efficiency. The commitment to safety not only protects workers but also fosters a culture of responsibility and care within the mining community.

Keywords:

Related News

Ensuring Safety in Mining: A Comprehensive Guide to Extractive Explosion-Proof Local Ventilators

Ensuring Safety in Mining: A Comprehensive Guide to Extractive Explosion-Proof Local Ventilators

Table of Contents

Introduction to Mining Safety and Ventilation

The Importance of Ventilation in Mining Operations

Key Safety Regulations for Mining Ventilation Systems

Understanding Extractive Explosion-Proof Local Ventilators

Design Considerations for Explosion-Proof Ventilat

15 Sep,2025

Maximizing Efficiency: The Role of Extractive Axial Flow Fans in Tunnel Construction

In the realm of tunnel construction, maintaining optimal air quality and effective ventilation is crucial for the safety and productivity of workers. Extractive axial flow fans play a significant role in this process, particularly in environments where dust, harmful gases, and other pollutants can accumulate. These fans are specifically designed to move large volumes of air efficiently, making the

12 Sep,2025

The Advantages of Counter-Rotating Axial Flow Fans in Mining Ventilation

Counter-rotating axial flow fans are an advanced solution for enhancing ventilation in various industrial applications, especially in the coal mining sector. These fans consist of two rotors that spin in opposite directions, creating a more efficient airflow compared to traditional fans. This design principle not only optimizes performance but also provides several advantages that can significantl

11 Sep,2025