Why Extractive Axial Flow Fans are Essential for Safe Tunnel Ventilation

2025-10-03

Understanding Extractive Axial Flow Fans and Their Importance in Tunnel Ventilation

In the world of coal mining, ensuring a safe and breathable environment within tunnels is paramount. **Extractive axial flow fans** are crucial in this context, facilitating effective ventilation and helping to mitigate the risks associated with harmful gases and dust. This article explores the intricacies of the

Understanding Extractive Axial Flow Fans and Their Importance in Tunnel Ventilation

In the world of coal mining, ensuring a safe and breathable environment within tunnels is paramount. **Extractive axial flow fans** are crucial in this context, facilitating effective ventilation and helping to mitigate the risks associated with harmful gases and dust. This article explores the intricacies of these fans, their operational mechanics, and the undeniable benefits they bring to tunnel ventilation.

What Are Extractive Axial Flow Fans?

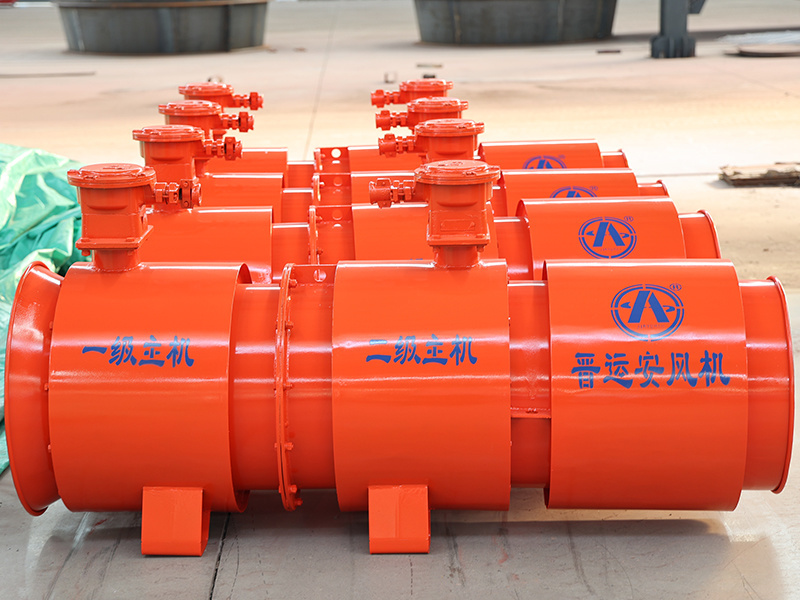

Extractive axial flow fans are specialized ventilation devices designed to move air efficiently through tunnels, shafts, and other confined spaces. They operate on the principle of axial flow, meaning the airflow direction is parallel to the axis of the fan. This design allows for high volumes of air to be moved quickly, making them ideal for applications in mining, construction, and other heavy industries.

Key Components of Extractive Axial Flow Fans

To appreciate the functionality of extractive axial flow fans, it’s essential to understand their key components:

- **Fan Blades**: These are typically constructed from durable materials designed to withstand harsh mining environments. The angle and design of the blades greatly influence airflow efficiency.

- **Motor**: The motor powers the fan, providing the necessary torque to rotate the blades at high speeds.

- **Housing**: The fan housing ensures optimal airflow while protecting the internal components from dust and debris.

- **Control System**: Advanced models come equipped with control systems that allow for the regulation of airflow based on real-time conditions in the tunnel.

How Extractive Axial Flow Fans Work

The operation of extractive axial flow fans is relatively straightforward yet highly effective. When activated, the motor drives the blades to rotate, creating a low-pressure area behind the fan. This pressure difference pulls air from the tunnel into the fan and pushes it out, thus creating a continuous flow of air. This mechanism is vital for diluting and removing hazardous gases, dust, and heat from mining operations.

The Role of Tunnel Ventilation in Mining Safety

Effective ventilation is critical in mining operations for several reasons:

- **Reduction of Harmful Gases**: Coal mines often contain dangerous gases, such as methane and carbon monoxide. Proper ventilation using extractive axial flow fans helps dilute these gases to safe levels.

- **Dust Control**: The mining process creates significant amounts of dust, which can impair visibility and pose health risks. Ventilation systems help to minimize dust accumulation.

- **Temperature Regulation**: Mining operations can generate excessive heat, which can be detrimental to worker safety and equipment efficiency. Axial flow fans help to maintain a stable and comfortable temperature.

Benefits of Using Extractive Axial Flow Fans in Tunnel Ventilation

The advantages of implementing extractive axial flow fans in tunnel ventilation systems include:

- **High Efficiency and Performance**: These fans are designed to move large volumes of air quickly, ensuring effective ventilation even in extensive tunnel systems.

- **Durability**: Built to withstand the challenging conditions of mining environments, extractive axial flow fans are often made from corrosion-resistant materials.

- **Cost-Effectiveness**: By reducing the need for more complex ventilation systems, extractive axial flow fans can provide a cost-effective solution for maintaining safe working conditions.

- **Flexibility**: These fans can be used in various applications, not only in coal mines but also in construction sites, tunnels, and other confined spaces requiring air movement.

Installation and Maintenance of Extractive Axial Flow Fans

Proper installation and maintenance are critical for the optimal performance of extractive axial flow fans. Here’s a quick overview of best practices:

- **Installation**: Fans should be installed in locations where airflow is most needed, considering factors such as obstructions and air quality.

- **Routine Maintenance**: Regular checks on the fan blades, motor, and housing are essential. Lubricating moving parts and cleaning dust and debris can significantly enhance performance.

- **Monitoring Systems**: Integrating monitoring systems can help in tracking fan performance and detecting issues before they become significant problems.

Application of Extractive Axial Flow Fans in Coal Mining

In coal mining, extractive axial flow fans find several critical applications:

- **Main Ventilation Systems**: They serve as the backbone of main ventilation systems, ensuring a continuous flow of fresh air into the mine.

- **Emergency Ventilation**: In the event of a gas leak or fire, extractive axial flow fans can be utilized to quickly ventilate the area, safeguarding workers.

- **Dust Suppression**: These fans help maintain air quality by removing airborne particulates generated during mining processes.

Regulatory Standards and Compliance for Ventilation Systems

Mining operations are subject to strict regulatory standards regarding air quality and worker safety. Compliance with these standards is essential to maintain operational licenses and ensure the safety of all personnel.

- **Occupational Safety and Health Administration (OSHA)**: OSHA sets regulations for ventilation systems in mining to minimize hazards related to air quality.

- **Mine Safety and Health Administration (MSHA)**: MSHA provides guidelines for the effective design and operation of ventilation systems, including the use of extractive axial flow fans.

Future Trends in Tunnel Ventilation Technology

As technology continues to evolve, so do the systems used for tunnel ventilation. Several trends are shaping the future of extractive axial flow fans:

- **Smart Technology Integration**: Upcoming models may incorporate smart technology, enabling real-time monitoring and automated adjustments based on air quality.

- **Sustainability**: Manufacturers are increasingly focusing on producing energy-efficient fans that minimize environmental impact while maximizing performance.

- **Modular Designs**: Future fan designs may offer modular components that allow for easier upgrades and maintenance.

Frequently Asked Questions

1. **What is the primary function of extractive axial flow fans in mining?**

Extractive axial flow fans primarily facilitate the movement of air to ensure safe and breathable conditions within tunnels.

2. **How do I know if my ventilation system is working effectively?**

Regular monitoring of air quality and flow rates can help determine the effectiveness of your ventilation system.

3. **What maintenance is required for extractive axial flow fans?**

Maintenance includes checking for wear and tear, lubricating moving parts, and ensuring the fan blades are clean and free of obstructions.

4. **Can extractive axial flow fans be used in other applications outside of mining?**

Yes, these fans are versatile and can be utilized in construction, underground tunnels, and other confined spaces requiring proper ventilation.

5. **What are the safety regulations regarding tunnel ventilation systems?**

Ventilation systems must comply with standards set by OSHA and MSHA, which outline requirements for air quality and worker safety in mining operations.

Conclusion

In conclusion, **extractive axial flow fans** play an indispensable role in ensuring safe tunnel ventilation in mining operations. By facilitating the movement of air, these fans help mitigate risks associated with harmful gases, dust, and excessive heat. Their efficiency, durability, and adaptability make them a crucial component of effective ventilation systems. As technology advances and regulations evolve, the continued development of these fans will be vital for maintaining safe working environments in the ever-challenging world of coal mining.

Keywords:

Related News

Why Extractive Axial Flow Fans are Essential for Safe Tunnel Ventilation

Understanding Extractive Axial Flow Fans and Their Importance in Tunnel Ventilation

In the world of coal mining, ensuring a safe and breathable environment within tunnels is paramount. **Extractive axial flow fans** are crucial in this context, facilitating effective ventilation and helping to mitigate the risks associated with harmful gases and dust. This article explores the intricacies of the

03 Oct,2025

Understanding Flameproof Push-In Axial Flow Fans for Coal Mines

In the demanding environment of coal mining, the need for effective ventilation and dust control is paramount. Flameproof push-in axial flow fans are specifically designed to meet these requirements, ensuring the safety and operational efficiency of coal mine operations. These fans are engineered to handle the unique challenges of mining, including the presence of flammable gases and dust, making

30 Sep,2025

How Counter-Rotating Axial Flow Fans Enhance Mine Health and Safety Protocols

How Counter-Rotating Axial Flow Fans Enhance Mine Health and Safety Protocols

Table of Contents

Introduction to Counter-Rotating Axial Flow Fans

The Importance of Health and Safety in Mining

Understanding Mine Ventilation Systems

Functionality of Counter-Rotating Axial Flow Fans

Key Benefits of Using Counter-Rotating Fans in Mining

Dust Control Mechanisms in Mines

Regu

27 Sep,2025