Product Categories

Contact Us

Email

sales@sxjyafan.com

Service Hotline:

+86-400-9944-001

Service Hotline:

+86-359-2480001

+86-13835937772

Intelligent local ventilation fan

Wide variety, support customization, superior performance, worry-free after-sales service.Products can fully meet the ventilation needs of various scenarios such as mines and tunnels, and are exported to many different fields at home and abroad.

Products

Keywords:

Category:

Product Details

System Overview

The intelligent local ventilation system for mines is a multi-functional, energy-efficient automatic control device designed to ensure safe mine production. It integrates the mine's local ventilation control system with local ventilation fans. The system is equipped with specially designed local ventilation fans, monitoring sensors, and other monitoring signals that are connected to a PLC automatic control system for closed-loop control. This changes the previous situation in China where the operation of local ventilation fans lacked effective monitoring and control. It organically combines effective mine management with safe and efficient equipment operation, thereby mitigating the hazards caused by gas in mine development faces. This improves equipment operational safety while ensuring safe and efficient mine production.

The system consists of a host computer, local ventilation fans, a variable frequency speed control device, intelligent control, and an air distributor.

Composition and Function

(1) Product Composition

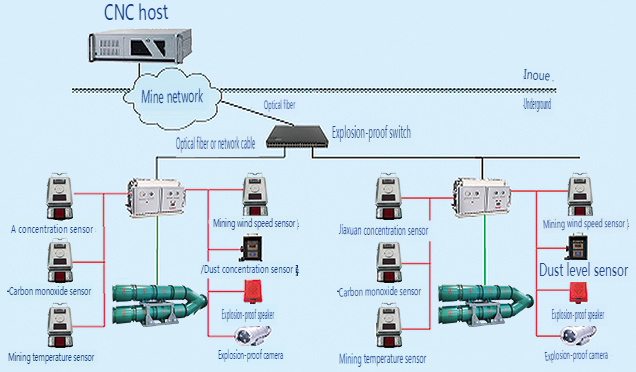

The device consists of a variable frequency drive, PLC, switching components, methane concentration sensor, temperature sensor, anemometer, carbon monoxide sensor, dust sensor, broadcasting system, network system, and the fan unit itself (see Figure 2).

The explosion-proof switch is placed at the mine's power distribution point and connected to the mine's ring network switch, ensuring both uninterrupted power supply and network connectivity. The connection between the explosion-proof switch and the intelligent variable frequency drive can be via network cable or fiber optic cable. Network cable is selected for short distances (within 100 meters), and fiber optic cable is selected for longer distances. The intelligent variable frequency drive has built-in Ethernet and fiber optic interfaces. Video and sensor data are transmitted via Ethernet to the host computer in the dispatch room.

Figure 2 Intelligent Network System Composition Structure

(2) Functions and Principles

Speed Control Device Operating Modes: The control mode is set based on the collected gas, temperature, wind speed, CO, and dust signals.

According to the "Safety Regulations," conventional speed regulation is based on methane concentration and includes three operating modes: "Self-Control Ventilation Mode," "Self-Control Gas Discharge Mode," and "Manual Frequency Setting Mode."

Self-Control Ventilation Mode

For low-gas mines, when the methane concentration at the working face heading and return air area does not exceed the set value, the speed control device operates in self-control ventilation mode. It switches to comprehensive control of the fan speed based on roadway air volume, temperature, CO content, and dust content. When any of these parameters at any measuring point exceeds the set value, the speed control device will automatically increase the speed and increase the air supply (upper limit frequency) until the exceeding signal returns to below the set safety value. Then, the fan speed will decrease (lower limit frequency). During this process, the methane concentration must remain below the safety value. Any excess will immediately switch to the self-control gas discharge mode.

——Upper limit frequency setting range: 30~50Hz

——Lower limit frequency setting range: 20~45Hz

——Speed control range of the speed control device in self-control ventilation mode: Between the set values of the lower and upper limit frequencies.

The location and number of airflow, CO, dust, and temperature signal points are reasonably arranged according to the actual underground conditions.

The intelligent local ventilation system can be linked to the mine's existing personnel positioning system and vehicle positioning system to adjust the speed and automatically control the air volume based on personnel and vehicle changes.

Self-Control Gas Discharge

The speed control device normally operates in self-control ventilation mode. When the actual concentration at the working face heading ≥ the set value at the working face heading or the actual concentration in the return air area ≥ the set value in the return air area, it will automatically switch to the self-control gas discharge mode. The fan speed is automatically adjusted according to the methane concentration at the working face heading. As the concentration at the working face heading increases, the fan speed decreases; conversely, as the concentration decreases, the fan speed increases, adjusting the fan's air output to prevent gas exceeding limits.

When the actual concentration at the working face heading ≥1.5%, the speed control device will automatically stop running. When the actual concentration at the working face heading drops to the restart set value, the speed control device will automatically restart. When the actual concentration at the working face heading < the set value at the working face heading and the actual concentration in the return air area < the set value in the return air area, it will automatically switch to the automatic ventilation mode after 10 minutes.

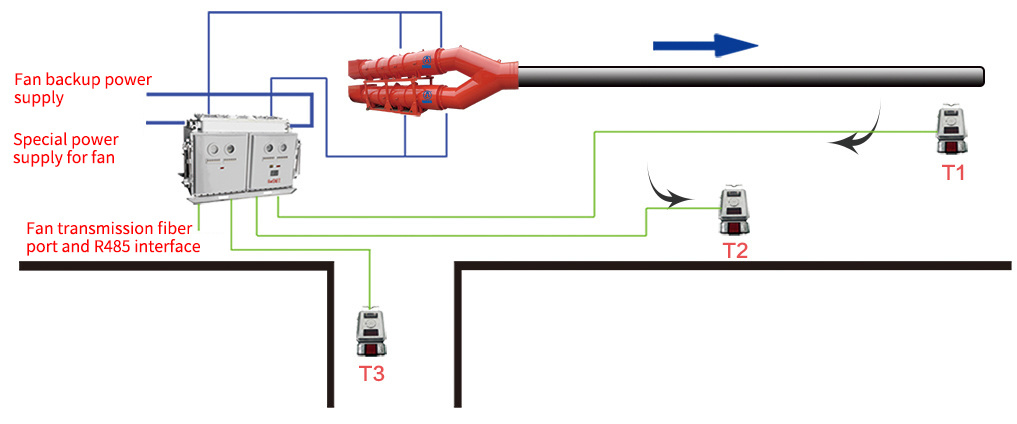

(3) "Dual-Machine Standby" Operating Mode

"Dual-machine standby" is the switching function between the main and standby speed control devices. The speed control device controls the automatic switching of two sets of locally ventilated fans powered by independent power supplies with the following functions:

(1) When the main ventilation fan starts automatically, the standby ventilation fan is in standby mode.

(2) When the main ventilation fan stops running or loses power, the standby ventilation fan starts automatically in automatic mode.

(3) When the main ventilation fan is running, if the main ventilation fan malfunctions, the standby ventilation fan immediately starts automatically. After the main ventilation fan malfunction is resolved, the main ventilation fan can be started by pressing the start button. The main ventilation fan will automatically start when the output frequency of the standby ventilation fan drops to 0Hz.

(4) Wind and Electricity Interlock and Function Introduction

Wind and Electricity Interlock: The main speed control device starts, and when the output frequency reaches 20Hz, the output node closes. When the main speed control device stops, the output node opens. (Note: This node is used to control the power supply of the power equipment).

Gas and Electricity Interlock: When the speed control device is in "automatic" operation, when the input methane concentration (return air area ≥1.5%) or (working face heading ≥1.0%), the output node opens (Note: This node is used to control the power supply of power equipment).

Display: The host computer configuration software needs to monitor the operation of the local fans in each working face simultaneously. When a fault alarm or intrusion alarm occurs in a working face, the alarm indicator light flashes, and the sound system emits an alarm sound. Clicking this alarm light displays detailed alarm information. For intrusion alarms, clicking the camera icon opens the camera view for that working face. To broadcast a notification to personnel working in that working face, click the broadcast control icon to open the broadcast control page.

To control or set a local fan in a certain working face, click the control and setting icon to open the corresponding control setting page. Control and settings require administrator login.

Fan bearing temperature and vibration detection: Some system functions are added based on the customer's on-site fan conditions, such as fan bearing temperature and vibration detection. The motor bearings of the fan are the most easily damaged parts of the fan. When the bearing temperature exceeds the set temperature, an alarm will be triggered, and maintenance personnel can promptly repair the fan to avoid emergencies.

Fan maintenance reminder function: This system adds a fan usage and maintenance reminder function. It stores and calculates the fan usage time and can be set according to the manufacturer's maintenance manual. It provides timely reminders to avoid forgetting or overdue maintenance, greatly improving the service life of the fan and making fan maintenance more user-friendly.

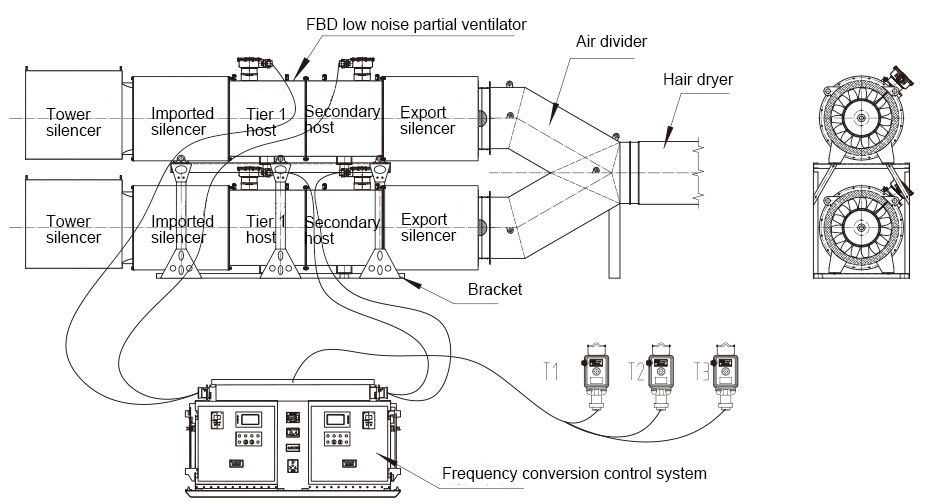

Split-type intelligent fan configuration diagram

The device consists of a dual-fan local ventilation system, an automatic switching air distributor, a fan bracket, a frequency converter, a PLC, switching components, a gas concentration sensor, a temperature sensor, an air speed sensor, a carbon monoxide sensor, a dust sensor, a broadcast system, a network system, and the fan itself. Functions can be added or reduced according to needs.

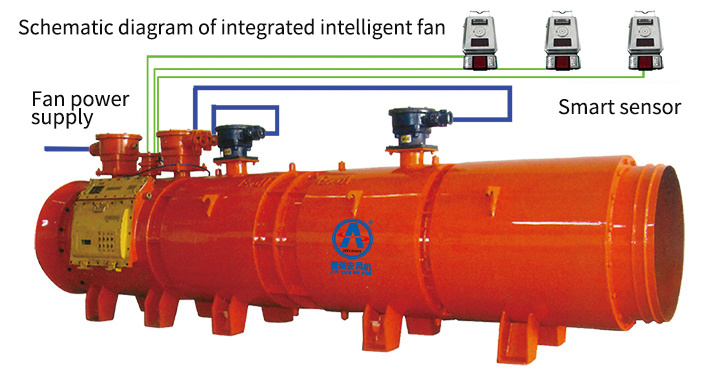

Integrated intelligent fan configuration diagram

The integrated intelligent fan device is a new product developed by our company, which combines the frequency converter and the local ventilation fan into one. The heat sink of the local ventilation fan's duct-type frequency conversion speed control device is installed in the duct of the local ventilation fan. When the local ventilation fan is working, the high-speed airflow generated passes through the surface of the heat sink and the motor casing, improving the heat dissipation efficiency of the heat sink and the motor.

Three-way air distributor

Local ventilation fan with Y-type and T-type ducts

Axial flow local ventilation fan with switchable Y-type or T-type three-way duct

Application scope

During the mining exploration and mining process, local ventilation fans are used for ventilation, dust removal, and dilution of harmful gases in aspects such as well shaft excavation, roadway coal mining, and pressure equalization ventilation. According to the requirements of the mine safety operating procedures, local ventilation fans are used for ventilation in the excavation working face. Ventilation is not allowed to be stopped during work or shift handover. However, if power must be cut off due to reasons such as maintenance or power failure, personnel must be evacuated and the power supply must be cut off as required. This will cause economic losses due to production stoppage and may also cause safety problems such as exceeding the local gas limit underground. Therefore, our company has specially designed a dual-fan automatic switching Y-type three-way duct and T-type three-way duct for the purpose of achieving one ventilation and three protections. Users can choose according to their needs.

External structure

|

Y-type automatic switching three-way The Y-type automatic switching three-way connects the duct and is often used on dual-fan local ventilation fans or intelligent fans. It is designed to ensure rapid switching when the fan is in a one-in-use, one-in-reserve state. Our company's designed Y-type automatic switching three-way connecting duct has a simple and reasonable structure, strong linearity, convenient hoisting, and light weight. The internal design includes an automatic switching tongue that can automatically switch according to the pressure of the fan ventilation flow path, with strong airtightness and no air leakage; flange connections or duct cloth soft connections are set at the fan connection points for easy user connection and installation; it can also be customized according to user's on-site needs. Commonly used Y-type duct models include: Y-FT-№4.5, Y-FT-№5.0, Y-FT-№5.6, Y-FT-№6.0, Y-FT-№6.3, Y-FT-№6.7, Y-FT-№7.1, Y-FT-№7.5, Y-FT-№8.0, Y-FT-№10.0, and other specifications. |

|

T-type switching three-way The T-type three-way connecting duct can be used for gas detection or air duct distribution. A switching damper is set at the short interface, which can be opened or closed by the user as needed. Our company's designed T-type switching three-way connecting duct can be designed to be 90 degrees or 45 degrees according to user needs; open and close limit slots are designed at the damper, with strong airtightness and no air leakage; flange connections or duct cloth soft connections are set at the fan connection points for easy connection and installation with the duct cloth; it can also be customized according to user's on-site needs. When customizing, the user needs to provide the size of the matching duct and the outlet of the matching fan. |

|

Working method

The company's main business is the design, research and development, and manufacturing of various ventilators and their supporting products for mines, non-coal mines, and rail transit. Products involve 38 series of fan products, more than 3,000 specifications, including FB(D) series, FBC(D)Z series, FKZ series, rail transit SDS series, tunnel SDF series, etc.; supporting products include shaft, inclined shaft self-resetting explosion-proof doors, louver-type automatic regulating air doors, side-opening (vertical) automatic regulating air doors, butterfly valves, silencers, main ventilator online detection and fault diagnosis systems, non-stop fan reverse systems and intelligent oil injection systems, which can fully meet the ventilation needs of mines and are sold to various domestic fields and international markets such as Russia and Canada.

In recent years, the company has successively won the honorary titles of "Yuncheng Enterprise Technology Center", "Yuncheng Excellent Enterprise", "Yuncheng Intellectual Property Demonstration Enterprise", and "Innovative Small and Medium-sized Enterprise". The company has passed the "ISO9001 Quality Management System Certification", "ISO14001 Environmental Management System Certification", "ISO45001 Occupational Health and Safety Management System Certification", and its products have passed the "China National Compulsory Product Certification". It has also obtained a number of patents. With advanced process equipment, strong technical strength, excellent product quality, and a perfect service system, it has won unanimous recognition and praise from users. In particular, the green, environmentally friendly, and low-noise fans that have been focused on the market in recent years have achieved rapid development, becoming a well-known enterprise in the fan industry with leading technology.

Previous Page:

Next Page:

Product Inquiry

*Please leave your phone number, we will contact you within 24 hours!