Product Categories

Contact Us

Email

sales@sxjyafan.com

Service Hotline:

+86-400-9944-001

Service Hotline:

+86-359-2480001

+86-13835937772

FKCDZ Main Ventilation Fan

Wide variety, support customization, superior performance, worry-free after-sales service.Products can fully meet the ventilation needs of various scenarios such as mines and tunnels, and are exported to many different fields at home and abroad.

Products

Keywords:

Category:

Product Details

I. Main Uses and Applicable Scope

Mine explosion-proof axial flow main ventilation fans are high-efficiency and energy-saving forced mechanical ventilation equipment specially designed for various coal mines, mines, and tunnels, often using an extraction ventilation structure. This series of fans can be designed and manufactured in combination with the ventilation network parameters of large, medium-sized coal mines or mines; this ventilation fan adopts an adjustable installation angle design, and can adjust the blade installation angle in time according to the changes in the working conditions of the mine ventilation network, so that the ventilation fan can always be in high-efficiency and energy-saving operation, and adopts an integral structure form of motor and impeller direct connection, eliminating the transmission system, with many advantages such as high efficiency, energy saving, low noise, simple installation and disassembly. This ventilation fan is also suitable for metal mines, chemical mines and other factories and mines that require forced ventilation.

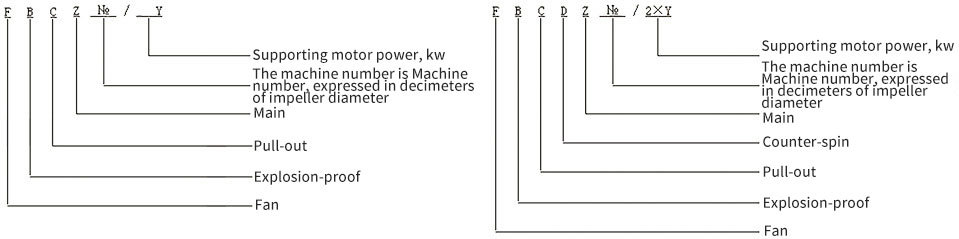

II. Model and Meaning

The performance curves of the ventilation fans are all obtained through actual simulation experiments on standard pipe networks, and are calculated and drawn under standard conditions of gas temperature t=20℃, gas density ρ=1.2kg/m 3 and atmospheric pressure P=101325Pa.

1. Fan Model and Representation Method

2. Model Definition Explanation

Taking FBCDZ№28/2×400 as an example: F—fan; B—explosion-proof; C—extraction type; D—counter-rotating; Z—main ventilation; №28—machine number, represented by the decimeter number of the impeller diameter; 2×400—installed power, 2 indicates two motors, 400kW power, unit kW.

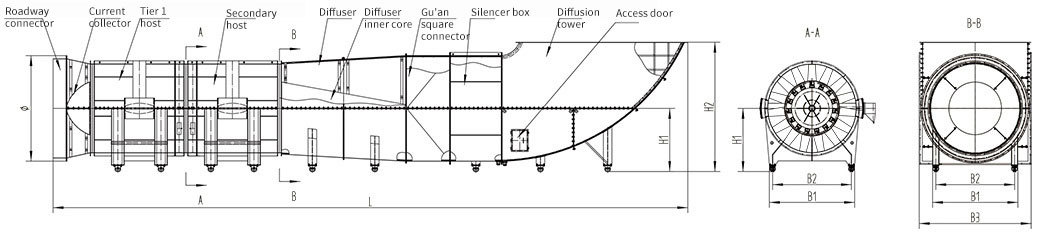

III. Outline Structural Diagram

Performance Parameters and Dimensions of FBCDZ (Original BDK) Series Ventilation Fans

|

Series |

Machine Number |

Installed Power (kW) |

Air Volume (m³/s) |

Air Pressure (Pa) |

Dimensions |

|||||||

| Φ |

D |

L |

B1 |

B2 |

B3 |

H |

H1 |

|||||

|

FBCDZ(B)-4 n=1480r/min

|

11 |

2×45 |

17~33 |

830~2670 |

1460 |

1100 |

6940 |

1140 |

900 |

1450 |

900 |

1995 |

|

12 |

2×55 |

19~37 |

970~3200 |

1580 |

1200 |

7535 |

1240 |

1050 |

1580 |

965 |

2055 |

|

|

13 |

2×75 |

27~48 |

1200~3700 |

1700 |

1300 |

8155 |

1340 |

1150 |

1700 |

1025 |

2115 |

|

|

14 |

2×110 |

32~59 |

1300~4400 |

1840 |

1400 |

9035 |

1440 |

1250 |

1840 |

1085 |

1185 |

|

|

FBCDZ(A)-6 n=980r/min |

15 |

2×37 |

19~47 |

225~1750 |

1960 |

1500 |

9900 |

1250 |

1425 |

1935 |

1240 |

2210 |

|

16 |

2×55 |

23~53 |

450~1970 |

2090 |

1600 |

10815 |

1345 |

1520 |

2050 |

1300 |

2330 |

|

|

17 |

2×75 |

27~64 |

460~2200 |

2160 |

1700 |

11480 |

1440 |

1615 |

2170 |

1360 |

2455 |

|

|

18 |

2×90 |

33~75 |

520~2500 |

2360 |

1800 |

12190 |

1515 |

1710 |

2290 |

1380 |

2560 |

|

|

19 |

2×110 |

41~91 |

600~2780 |

2460 |

1900 |

13085 |

1610 |

1805 |

2410 |

1410 |

2640 |

|

|

20 |

2×160 |

45~104 |

730~3150 |

2560 |

2000 |

14210 |

1705 |

1900 |

2530 |

1480 |

2785 |

|

|

21 |

2×220 |

52~118 |

750~3370 |

2560 |

2100 |

14930 |

1805 |

2000 |

1645 |

1530 |

2895 |

|

|

22 |

2×280 |

61~134 |

810~3720 |

2760 |

2200 |

14965 |

1895 |

2090 |

2760 |

1585 |

3025 |

|

|

FBCDZ(A)-8 n=740r/min |

18 |

2×45 |

25~56 |

320~1450 |

2360 |

1800 |

12190 |

1515 |

1710 |

2290 |

1380 |

2560 |

|

19 |

2×55 |

29~67 |

360~1620 |

2460 |

1900 |

13085 |

1610 |

1805 |

2410 |

1410 |

2640 |

|

|

20 |

2×75 |

34~78 |

380~1750 |

2560 |

2000 |

14210 |

1705 |

1900 |

2530 |

1480 |

2785 |

|

|

21 |

2×90 |

41~89 |

440~1940 |

2560 |

2100 |

14930 |

1805 |

2000 |

1645 |

1530 |

2895 |

|

|

22 |

2×110 |

46~106 |

480~2170 |

2760 |

2200 |

14965 |

1895 |

2090 |

2760 |

1585 |

3025 |

|

|

23 |

2×132 |

53~118 |

550~2320 |

2760 |

2300 |

16080 |

1990 |

2185 |

2930 |

1670 |

3160 |

|

|

24 |

2×185 |

58~133 |

600~2540 |

2970 |

2400 |

16245 |

2085 |

2280 |

3050 |

1720 |

3280 |

|

|

25 |

2×220 |

64~150 |

630~2700 |

2970 |

2500 |

17620 |

2100 |

2375 |

3165 |

1840 |

3465 |

|

|

26 |

2×250 |

73~169 |

700~2970 |

3160 |

2600 |

18700 |

2140 |

2470 |

3280 |

1900 |

3590 |

|

|

FBCDZ(B)-6 n=980r/min |

12 |

2×18.5 |

13~26 |

450~1500 |

1580 |

1200 |

7535 |

1240 |

1050 |

1580 |

965 |

2055 |

|

13 |

2×30 |

16~33 |

500~1780 |

1700 |

1300 |

8155 |

1340 |

1150 |

1700 |

1025 |

2115 |

|

|

14 |

2×45 |

19~42 |

600~2100 |

1840 |

1400 |

9035 |

1440 |

1250 |

1840 |

1085 |

1185 |

|

|

15 |

2×55 |

23~51 |

660~2300 |

1960 |

1500 |

9900 |

1250 |

1425 |

1935 |

1240 |

2210 |

|

|

16 |

2×75 |

28~60 |

830~2640 |

2100 |

1600 |

10815 |

1345 |

1520 |

2050 |

1300 |

2330 |

|

|

17 |

2×110 |

34~73 |

880~2900 |

2160 |

1700 |

11480 |

1440 |

1615 |

2170 |

1360 |

2455 |

|

|

18 |

2×132 |

40~86 |

920~3400 |

2360 |

1800 |

12190 |

1515 |

1710 |

2290 |

1380 |

2560 |

|

|

19 |

2×185 |

48~103 |

1000~3600 |

2460 |

1900 |

13085 |

1610 |

1805 |

2410 |

1410 |

2640 |

|

Performance Parameters and Dimensions of FBCDZ (Original BDK) Series Ventilation Fans

|

Series |

Machine Number |

Installed Power (kW) |

Air Volume (m³/s) |

Air Pressure (Pa) |

Dimensions |

|||||||

| Φ |

D |

L |

B1 |

B2 |

B3 |

H |

H1 |

|||||

|

FBCDZ(B)-6 n=980r/min |

20 |

2×220 |

55~119 |

1170~4100 |

2560 |

2000 |

14210 |

1705 |

1900 |

2530 |

1480 |

2785 |

|

21 |

2×280 |

61~135 |

1200~4300 |

2560 |

2100 |

14930 |

1805 |

2000 |

1645 |

1530 |

2895 |

|

|

22 |

2×355 |

72~160 |

1400~4900 |

2760 |

2200 |

14965 |

1895 |

2090 |

2760 |

1585 |

3025 |

|

|

FBCDZ(B)-8 n=740r/min |

18 |

2×75 |

31~67 |

520~1900 |

2360 |

1800 |

12190 |

1515 |

1710 |

2290 |

1380 |

2560 |

|

19 |

2×90 |

35~77 |

600~2100 |

2460 |

1900 |

13085 |

1610 |

1805 |

2410 |

1410 |

2640 |

|

|

20 |

2×110 |

43~89 |

670~2300 |

2560 |

2000 |

14210 |

1705 |

1900 |

2530 |

1480 |

2785 |

|

|

21 |

2×132 |

49~104 |

730~2520 |

2560 |

2100 |

14930 |

1805 |

2000 |

1645 |

1530 |

2895 |

|

|

22 |

2×160 |

57~120 |

800~2800 |

2760 |

2200 |

14965 |

1895 |

2090 |

2760 |

1585 |

3025 |

|

|

23 |

2×185 |

63~136 |

900~3100 |

2760 |

2300 |

16080 |

1990 |

2185 |

2930 |

1670 |

3160 |

|

|

24 |

2×250 |

72~155 |

1000~3400 |

2970 |

2400 |

16245 |

2085 |

2280 |

3050 |

1720 |

3280 |

|

|

25 |

2×315 |

83~172 |

1100~3700 |

2970 |

2500 |

17620 |

2100 |

2375 |

3165 |

1840 |

3465 |

|

|

26 |

2×355 |

92~198 |

1130~3900 |

3160 |

2600 |

18700 |

2140 |

2470 |

3280 |

1900 |

3590 |

|

|

27 |

2×450 |

103~221 |

1300~4300 |

3160 |

2700 |

18860 |

2240 |

2570 |

3395 |

1960 |

3710 |

|

|

28 |

2×500 |

115~245 |

1360~4570 |

3395 |

2800 |

19595 |

2330 |

2660 |

3545 |

2030 |

3845 |

|

|

29 |

2×630 |

120~274 |

1400~4900 |

3395 |

2900 |

19710 |

2425 |

2755 |

3710 |

2120 |

3985 |

|

|

30 |

2×710 |

138~304 |

1480~5200 |

3590 |

3000 |

21130 |

2520 |

2850 |

2830 |

2180 |

4105 |

|

|

FBCDZ(B)-10 n=580r/min |

24 |

2×132 |

57~122 |

590~2050 |

2970 |

2400 |

16245 |

2085 |

2280 |

3050 |

1720 |

3280 |

|

25 |

2×160 |

64~139 |

620~2300 |

2970 |

2500 |

17620 |

2100 |

2375 |

3165 |

1840 |

3465 |

|

|

26 |

2×185 |

73~156 |

680~2450 |

3160 |

2600 |

18700 |

2140 |

2470 |

3280 |

1900 |

3590 |

|

|

27 |

2×220 |

82~177 |

720~2550 |

3160 |

2700 |

18860 |

2240 |

2570 |

3395 |

1960 |

3710 |

|

|

28 |

2×250 |

92~191 |

800~2800 |

3395 |

2800 |

19595 |

2330 |

2660 |

3545 |

2030 |

3845 |

|

|

29 |

2×315 |

100~215 |

890~3100 |

3395 |

2900 |

19710 |

2425 |

2755 |

3710 |

2120 |

3985 |

|

|

30 |

2×355 |

110~238 |

920~3200 |

3590 |

3000 |

21130 |

2520 |

2850 |

2830 |

2180 |

4105 |

|

|

31 |

2×450 |

123~262 |

950~3460 |

3590 |

3100 |

23645 |

2615 |

2945 |

3950 |

2260 |

4230 |

|

|

32 |

2×560 |

135~290 |

1030~3700 |

3590 |

3200 |

24975 |

2710 |

3040 |

4060 |

2295 |

4350 |

|

|

33 |

2×630 |

147~318 |

1100~3980 |

3990 |

3300 |

26340 |

2805 |

3135 |

4210 |

2360 |

4480 |

|

|

34 |

2×710 |

160~347 |

1160~4100 |

3990 |

3400 |

27630 |

2900 |

3230 |

4320 |

2420 |

4605 |

|

|

36 |

2×900 |

190~413 |

1400~4630 |

3990 |

3600 |

30260 |

3090 |

3420 |

4550 |

2535 |

4845 |

|

|

38 |

2×1100 |

223~480 |

1900~5150 |

4190 |

3800 |

32910 |

3280 |

3610 |

4785 |

2650 |

4971 |

|

Note: The parameters in this dimensional drawing are for reference only and are subject to change without notice.

Performance Parameters and Dimensions of FBCDZ (Original BDK) Series Ventilation Fans

|

Series |

Machine Number |

Installed Power (kW) |

Air Volume (m³/s) |

Air Pressure (Pa) |

Dimensions |

|||||||

| Φ |

D |

L |

B1 |

B2 |

B3 |

H |

H1 |

|||||

|

FBCDZ(B)-12 n=480r/min |

35 |

2×500 |

150~325 |

900~3280 |

3990 |

3500 |

28680 |

2995 |

3325 |

4440 |

2480 |

4720 |

|

36 |

2×560 |

165~356 |

950~3450 |

3990 |

3600 |

30260 |

3090 |

3420 |

4550 |

2535 |

4845 |

|

|

37 |

2×710 |

180~385 |

1000~3700 |

4190 |

3700 |

31590 |

3185 |

3515 |

4670 |

2595 |

4971 |

|

|

38 |

2×800 |

190~413 |

1100~3800 |

4190 |

3800 |

32910 |

3280 |

3610 |

4785 |

2650 |

4971 |

|

|

39 |

2×900 |

210~450 |

1170~4050 |

5090 |

3900 |

34230 |

3940 |

3750 |

5417 |

2810 |

5675 |

|

|

40 |

2×1000 |

220~490 |

1200~4300 |

5235 |

4000 |

36400 |

4040 |

3850 |

5570 |

2882 |

5825 |

|

|

41 |

2×1200 |

240~520 |

1300~4500 |

5335 |

4100 |

37730 |

4140 |

3950 |

5679 |

2932 |

5965 |

|

|

42 |

2×1300 |

260~555 |

1400~4700 |

5475 |

4200 |

39040 |

4240 |

4050 |

5827 |

3002 |

6095 |

|

|

FBCDZ(C)-6 n=980r/min |

17 |

2×110 |

25~58 |

850~3700 |

2160 |

1700 |

11480 |

1440 |

1615 |

2170 |

1360 |

2455 |

|

18 |

2×160 |

30~70 |

900~4200 |

2360 |

1800 |

12190 |

1515 |

1710 |

2290 |

1380 |

2560 |

|

|

19 |

2×185 |

35~82 |

1000~4750 |

2460 |

1900 |

13085 |

1610 |

1805 |

2410 |

1410 |

2640 |

|

|

20 |

2×250 |

41~96 |

1180~5200 |

2560 |

2000 |

14210 |

1705 |

1900 |

2530 |

1480 |

2785 |

|

|

21 |

2×280 |

45~117 |

1250~5300 |

2560 |

2100 |

14930 |

1805 |

2000 |

1645 |

1530 |

2895 |

|

|

22 |

2×355 |

52~121 |

1350~6700 |

2760 |

2200 |

14965 |

1895 |

2090 |

2760 |

1585 |

3025 |

|

|

FBCDZ(C)-8 n=740r/min |

18 |

2×75 |

22~53 |

520~2380 |

2360 |

1800 |

12190 |

1515 |

1710 |

2290 |

1380 |

2560 |

|

19 |

2×90 |

27~62 |

600~2600 |

2460 |

1900 |

13085 |

1610 |

1805 |

2410 |

1410 |

2640 |

|

|

20 |

2×110 |

31~67 |

650~2900 |

2560 |

2000 |

14210 |

1705 |

1900 |

2530 |

1480 |

2785 |

|

|

21 |

2×132 |

36~93 |

690~3600 |

2560 |

2100 |

14930 |

1805 |

2000 |

1645 |

1530 |

2895 |

|

|

22 |

2×185 |

41~97 |

790~3700 |

2760 |

2200 |

14965 |

1895 |

2090 |

2760 |

1585 |

3025 |

|

|

23 |

2×200 |

46~110 |

850~3900 |

2760 |

2300 |

16080 |

1990 |

2185 |

2930 |

1670 |

3160 |

|

|

24 |

2×250 |

54~125 |

900~4200 |

2970 |

2400 |

16245 |

2085 |

2280 |

3050 |

1720 |

3280 |

|

|

25 |

2×315 |

59~140 |

950~4600 |

2970 |

2500 |

17620 |

2100 |

2375 |

3165 |

1840 |

3465 |

|

|

26 |

2×400 |

68~159 |

1100~4900 |

3160 |

2600 |

18700 |

2140 |

2470 |

3280 |

1900 |

3590 |

|

|

27 |

2×450 |

77~178 |

1200~5400 |

3160 |

2700 |

18860 |

2240 |

2570 |

3395 |

1960 |

3710 |

|

|

28 |

2×500 |

85~200 |

1300~5800 |

3395 |

2800 |

19595 |

2330 |

2660 |

3545 |

2030 |

3845 |

|

|

29 |

2×630 |

92~220 |

1500~6200 |

3395 |

2900 |

19710 |

2425 |

2755 |

3710 |

2120 |

3985 |

|

|

30 |

2×710 |

104~245 |

1600~6700 |

3590 |

3000 |

21130 |

2520 |

2850 |

2830 |

2180 |

4105 |

|

|

FBCDZ(C)-10 n=580r/min |

24 |

2×132 |

42~98 |

550~2650 |

2970 |

2400 |

16245 |

2085 |

2280 |

3050 |

1720 |

3280 |

|

26 |

2×185 |

53~126 |

600~3100 |

3160 |

2600 |

18700 |

2140 |

2470 |

3280 |

1900 |

3590 |

|

|

28 |

2×280 |

66~155 |

700~3600 |

3395 |

2800 |

19595 |

2330 |

2660 |

3545 |

2030 |

3845 |

|

Performance Parameters and Dimensions of FBCDZ (Original BDK) Series Ventilation Fans

|

Series |

Machine Number |

Installed Power (kW) |

Air Volume (m³/s) |

Air Pressure (Pa) |

Dimensions |

|||||||

| Φ |

D |

L |

B1 |

B2 |

B3 |

H |

H1 |

|||||

|

FBCDZ(C)-10 n=580r/min |

30 |

2×400 |

81~190 |

900~4100 |

3590 |

3000 |

21130 |

2520 |

2850 |

2830 |

2180 |

4105 |

|

32 |

2×500 |

98~232 |

980~4700 |

3590 |

3200 |

24975 |

2710 |

3040 |

4060 |

2295 |

4350 |

|

|

34 |

2×710 |

129~270 |

1100~5200 |

3990 |

3400 |

27630 |

2900 |

3230 |

4320 |

2420 |

4605 |

|

|

36 |

2×900 |

140~330 |

1300~5800 |

3990 |

3600 |

30260 |

3090 |

3420 |

4550 |

2535 |

4845 |

|

|

38 |

2×1200 |

165~385 |

1400~6500 |

4190 |

3800 |

32910 |

3280 |

3610 |

4785 |

2650 |

4971 |

|

|

FBCDZ(C)-12 n=480r/min |

30 |

2×250 |

70~159 |

680~3000 |

3590 |

3000 |

21130 |

2520 |

2850 |

2830 |

2180 |

4105 |

|

32 |

2×355 |

86~203 |

780~3400 |

3590 |

3200 |

24975 |

2710 |

3040 |

4060 |

2295 |

4350 |

|

|

34 |

2×450 |

102~241 |

850~3800 |

3990 |

3400 |

27630 |

2900 |

3230 |

4320 |

2420 |

4605 |

|

|

36 |

2×630 |

122~282 |

900~4400 |

3990 |

3600 |

30260 |

3090 |

3420 |

4550 |

2535 |

4845 |

|

|

38 |

2×800 |

143~330 |

1050~4800 |

4190 |

3800 |

32910 |

3280 |

3610 |

4785 |

2650 |

4971 |

|

|

40 |

2×1000 |

170~390 |

1180~5400 |

5235 |

4000 |

36400 |

4040 |

3850 |

5570 |

2882 |

5825 |

|

|

42 |

2×1300 |

190~450 |

1300~6000 |

5475 |

4200 |

39040 |

4240 |

4050 |

5827 |

3002 |

6095 |

|

|

FBCDZ(D)-8 n=740r/min |

20 |

2×90 |

28~66 |

580~2900 |

2560 |

2000 |

14210 |

1705 |

1900 |

2530 |

1480 |

2785 |

|

22 |

2×160 |

37~94 |

650~3600 |

2760 |

2200 |

14965 |

1895 |

2090 |

2760 |

1585 |

3025 |

|

|

24 |

2×220 |

49~122 |

700~4300 |

2970 |

2400 |

16245 |

2085 |

2280 |

3050 |

1720 |

3280 |

|

|

25 |

2×280 |

56~138 |

800~4700 |

2970 |

2500 |

17620 |

2100 |

2375 |

3165 |

1840 |

3465 |

|

|

26 |

2×355 |

63~156 |

900~4900 |

3160 |

2600 |

18700 |

2140 |

2470 |

3280 |

1900 |

3590 |

|

|

FBCDZ(D)-10 n=580r/min |

24 |

2×110 |

38~96 |

500~2600 |

2970 |

2400 |

16245 |

2085 |

2280 |

3050 |

1720 |

3280 |

|

26 |

2×160 |

49~121 |

600~3000 |

3160 |

2600 |

18700 |

2140 |

2470 |

3280 |

1900 |

3590 |

|

|

28 |

2×250 |

63~150 |

650~3550 |

3395 |

2800 |

19595 |

2330 |

2660 |

3545 |

2030 |

3845 |

|

|

30 |

2×355 |

75~187 |

700~4100 |

3590 |

3000 |

21130 |

2520 |

2850 |

2830 |

2180 |

4105 |

|

|

32 |

2×450 |

93~225 |

750~4600 |

3590 |

3200 |

24975 |

2710 |

3040 |

4060 |

2295 |

4350 |

|

|

34 |

2×630 |

108~267 |

800~5200 |

3990 |

3400 |

27630 |

2900 |

3230 |

4320 |

2420 |

4605 |

|

|

FBCDZ(D)-12 n=480r/min |

32 |

2×315 |

80~192 |

700~3400 |

3590 |

3200 |

24975 |

2710 |

3040 |

4060 |

2295 |

4350 |

|

34 |

2×400 |

94~231 |

750~3800 |

3990 |

3400 |

27630 |

2900 |

3230 |

4320 |

2420 |

4605 |

|

|

36 |

2×560 |

110~278 |

800~4200 |

3990 |

3600 |

30260 |

3090 |

3420 |

4550 |

2535 |

4845 |

|

|

38 |

2×710 |

138~332 |

850~4800 |

4190 |

3800 |

32910 |

3280 |

3610 |

4785 |

2650 |

4971 |

|

|

40 |

2×900 |

155~380 |

900~5400 |

5235 |

4000 |

36400 |

4040 |

3850 |

5570 |

2882 |

5825 |

|

|

42 |

2×1200 |

175~438 |

950~5800 |

5475 |

4200 |

39040 |

4240 |

4050 |

5827 |

3002 |

6095 |

|

Note: The parameters in this dimensional drawing are for reference only and are subject to change without notice.

V. Operation and Maintenance

1. Before starting the fan, it is necessary to check whether there are any foreign objects in the flow channel to prevent the fan impeller from being impacted by foreign objects and damaged after starting.

2. Before starting the fan, please read the instruction manuals of the electrical control device, motor, secondary instrument, and fan carefully, and operate the equipment according to the requirements to prevent operational errors. First, fully open the air valve, and then start the fan in the order of secondary and then primary, ensuring normal operation of the fan. The general time interval for starting is about 2 minutes. When starting with frequency control, the primary and secondary stages can be started simultaneously.

3. After the fan is started and reaches normal operation, it is necessary to observe promptly: whether the operating current of the motor exceeds the rated current of the motor; whether there are any abnormal sounds in the fan flow channel. If a problem is found, stop the machine immediately for inspection. After the cause is found and the fault is eliminated, the machine can return to normal operation.

4. If the motor has a shutdown heater, the voltage is 220V. If the fan is left unused for a long time, the heater should be used to preheat the motor cavity first, and then put into operation after the insulation resistance meets the requirements.

5. During the use of the fan, there should be an operation log book to systematically record the operation status of the fan, including:

★ Start and stop times of the ventilation fan, reasons for shutdown.

★ Ambient temperature, humidity, and atmospheric pressure.

★ Working voltage and current of the motor, motor bearing temperature, and stator temperature.

★ Air pressure and air volume of the fan.

★ Time, quantity, and brand of lubricating grease added to the motor bearings.

★ Regular inspection of abnormal conditions found during operation.

|

Fault phenomenon |

Cause analysis |

Troubleshooting methods |

Remarks |

|

Blade friction against the housing |

1. Uneven blade clearance 2. Hub and motor shaft misalignment, blade deformation |

1. Perform impeller dynamic balancing test after shutdown. 2. Correct the blades |

When the fan has been running for a long time, it may occur due to mechanical operation |

|

Large vibration of the fan housing |

1. Insufficient impeller balance accuracy 2. The fan experiences surge 3. Dust and debris shedding from the blade surface |

1. Perform impeller dynamic balancing test after shutdown 2. Change in operating conditions, adjust to appropriate blade angle 3. Clean the dust and debris from the impeller surface |

|

|

Motor lubricating oil cannot be injected |

1. Air in the oil injection pipe 2. Poor oil drainage |

1. Clean the oil injection pipe 2. Add oil after shutdown |

|

|

High temperature rise of motor bearings or stator |

1. No lubricating oil in the motor 2. High ambient temperature 3. Motor manufacturing problem |

1. Inject lubricating oil 2. Contact the manufacturer for technical service |

|

|

Low stator insulation resistance |

Motor damp |

Slowly preheat using a heater before starting the fan |

The maximum temperature should not exceed 130℃ |

6. Regularly stop the machine to check whether the various components of the ventilation fan meet the requirements:

★ Check the front and rear bearings of the motor. If any problems are found, replace the bearings according to the requirements and replace the lubricating oil.

★ Check the impeller part of the ventilation fan, whether the blades are loose, whether the installation angle of the blades is the same as the setting. Deal with any problems promptly.

★ Check the impeller housing protective ring rivets for looseness or shedding every six months. If any, notify the manufacturer immediately.

7. During daily operation, pay attention to checking the reliability of the measuring instruments to prevent accidents caused by the failure of thermometers, ammeters, etc.

8. During shutdown and maintenance, if lubricating grease is replaced, the waste grease should be cleaned up, including the waste grease remaining in the oil injection pipe system. If cleaning with gasoline, wait until the gasoline evaporates completely before applying new grease. The new grease should be applied to the bearing track. The initial greasing should meet the following requirements: the bearing gap is filled, the entire bearing cavity is filled to about 75%, and the outer cover cavity is filled to about 30%.

9. The fan is equipped with a lubrication device that allows for lubrication without stopping. Use an oil gun for lubrication. At the start of operation, add 500g of grease every 720 hours; after 2000 hours, add 60g of grease every 1440 hours. If the ambient temperature changes significantly with the seasons, the lubrication time and amount can be divided into two levels according to temperatures ≤25℃ and ≥25℃. When the ambient temperature is high, the lubrication cycle should be shortened accordingly. When lubricating, drain the old grease at the same time. Recommended grease grade: LGWA2, SKF bearing special grease. If there are conflicts between some requirements and the contents of the random instruction manual, the random instruction manual shall prevail.

10. If the fan is shut down for a long time at low temperatures, be sure to check whether the grease has deteriorated before restarting. If the ambient temperature is too low, use a low-temperature resistant grease.

11. Regularly clean dust from the surface of the fan, electrical control system, and secondary instruments.

12. Personnel in the machine room should regularly conduct external inspections of the internal machine operation. If any abnormal sounds, vibrations, or temperature rises are detected, stop the machine immediately and address the issue. Restart only after the fault has been resolved.

VI. Packaging, Transportation, and Storage

1. The fan has been debugged and inspected before leaving the factory and uses simple packaging.

2. Small-sized fans are shipped as complete units, while large-sized fans are shipped in parts, including the main unit diffuser and the diffuser tower. The isolation chamber has undergone rigorous pressure testing. Users should generally not disassemble the isolation chamber from the main unit to avoid damaging the explosion-proof performance of the unit.

3. This series of fans can be transported by rail, road, or water.

4. When the fan is not in use for a long time, it should be placed in a cool, dry, ventilated place free of corrosive gases, and the ambient temperature and relative humidity should meet the technical requirements.

5. The packaging boxes of the motor, fan, and secondary instruments contain product qualification certificates, packing lists, and operation and maintenance instructions. The fan has been inspected and approved before leaving the factory.

The company's main business is the design, research and development, and manufacturing of various ventilators and their supporting products for mines, non-coal mines, and rail transit. Products involve 38 series of fan products, more than 3,000 specifications, including FB(D) series, FBC(D)Z series, FKZ series, rail transit SDS series, tunnel SDF series, etc.; supporting products include shaft, inclined shaft self-resetting explosion-proof doors, louver-type automatic regulating air doors, side-opening (vertical) automatic regulating air doors, butterfly valves, silencers, main ventilator online detection and fault diagnosis systems, non-stop fan reverse systems and intelligent oil injection systems, which can fully meet the ventilation needs of mines and are sold to various domestic fields and international markets such as Russia and Canada.

In recent years, the company has successively won the honorary titles of "Yuncheng Enterprise Technology Center", "Yuncheng Excellent Enterprise", "Yuncheng Intellectual Property Demonstration Enterprise", and "Innovative Small and Medium-sized Enterprise". The company has passed the "ISO9001 Quality Management System Certification", "ISO14001 Environmental Management System Certification", "ISO45001 Occupational Health and Safety Management System Certification", and its products have passed the "China National Compulsory Product Certification". It has also obtained a number of patents. With advanced process equipment, strong technical strength, excellent product quality, and a perfect service system, it has won unanimous recognition and praise from users. In particular, the green, environmentally friendly, and low-noise fans that have been focused on the market in recent years have achieved rapid development, becoming a well-known enterprise in the fan industry with leading technology.

Previous Page:

Next Page:

Product Inquiry

*Please leave your phone number, we will contact you within 24 hours!