Product Categories

Contact Us

Email

sales@sxjyafan.com

Service Hotline:

+86-400-9944-001

Service Hotline:

+86-359-2480001

+86-13835937772

Main fan non-stop reversal system for coal mines

Wide variety, support customization, superior performance, worry-free after-sales service.Products can fully meet the ventilation needs of various scenarios such as mines and tunnels, and are exported to many different fields at home and abroad.

Products

Keywords:

Category:

Product Details

I. Safety Solution for Overlimit Prevention in Ventilation Systems of High-Gas Coal Mines

The main ventilation fan in a coal mine is responsible for supplying sufficient fresh air underground, removing and diluting toxic and harmful gases and dust, regulating mine climate conditions, creating a good working environment, and improving the mine's disaster resistance. Most coal mines in China are high-gas mines, and whether the methane concentration exceeds the standard is a major factor affecting the safe production of the mine. Therefore, the importance of the mine ventilation system is self-evident. As the main provider of ventilation power, the main ventilation fan is known as the "mine's lungs." Its performance and work efficiency are closely related to the methane content in the mine. If the "ventilation instability" caused by the main ventilation fan is not handled promptly, it will lead to methane accumulation, exceeding limits, and even methane explosion accidents, which will have disastrous consequences for the safe production of coal mines.

At present, the ventilation equipment used in most mines has various shortcomings. It requires stopping the wind and reversing the machine, and the reversing time is too long. During this period, it is difficult to ensure the continuous supply of ventilation power during the downtime of the main ventilation fan, resulting in insufficient mine ventilation capacity for a short period of time, a temporary exceeding of the methane content at the bottom of the shaft, and a huge safety hazard, seriously threatening the safe production of the mine and the lives of workers. The mine main fan non-stop reversing system is a highly reliable underground ventilation system developed to address these safety hazards. It ends the history of needing to stop the wind to reverse the main fan, continuously providing sufficient air volume to the underground during mine production, strictly controlling the methane content in the underground air, and eliminating safety hazards caused by poor ventilation as much as possible.

● Function and Impact of the Main Fan Non-Stop Reversing System

For high-gas coal mines, methane accumulation and exceeding methane limits are major hidden dangers to safe production. The periodic reversing of the main fan with one in use and one in reserve faces a huge challenge in avoiding methane accumulation and exceeding methane limits, and the excessively long reversing time is unacceptable for general gas mines. Compared with the important causes of methane exceeding limits caused by the "failure and abnormal operation of the main ventilation fan," which lead to instability at the source of the coal mine ventilation system, methane exceeding limits accidents caused by the downtime of the main ventilation fan are more common. This is because the main ventilation fan, according to the traditional "stop-wind reversing" operation method, has "short-term wind stoppages" during the periodic reversing process, and because the standby fan is a cold standby method in the traditional "stop-wind reversing" mode, once the standby fan fails to start as expected due to an accident, the coal mine ventilation will be difficult to recover in a short time, forming ventilation instability. For "high-gas coal mines and coal and gas outburst mines," this easily leads to methane exceeding limits accidents, threatening the safe production of coal mines.

This system adopts the concept of hot standby for ventilation fans, ensuring the continuous supply of ventilation power during the downtime of the main ventilation fan. It has the functions of automatic reversing of the mine main ventilation fan without stopping the wind, "one-button" operation reversing, and automatic identification of the operation of the ventilation fan fault. Through the detection and control system, the logic control quickly opens or closes the airlock to achieve rapid switching of the ventilation fan, reducing the impact on the ventilation system during the reversing process from the "system wind stoppage" in the traditional way to "air volume fluctuation." The downtime in the fault state is shortened, reducing the original main fan ventilation fan downtime from more than five minutes or even ten minutes to a fluctuation in air volume of only about forty seconds. The use of this system improves this safe weak link of main fan ventilation fan downtime and has a great significance for the safe production of the mine.

In addition, the use of this system in high-gas coal mines will also bring considerable social and economic benefits. After the coal mine ventilation fan non-stop reversing project is put into operation, it eliminates the accumulation and exceeding limits of methane caused by ventilation interruption during downtime, eliminating safety hazards, improving the safety and reliability of the entire ventilation system, and effectively ensuring the safe production of coal mines, which has positive social benefits; the elimination of methane exceeding limits during the downtime of the main ventilation fan saves the time wasted in methane discharge due to downtime exceeding methane limits, providing a time guarantee for coal mine revenue generation, and achieving certain economic benefits.

II. Reversing Characteristics and Process of the Main Fan Non-Stop Reversing System

1. Reduce starting wind resistance and improve motor starting success rate

According to the starting characteristics of the ventilation fan, the magnitude and duration of its starting current are related to wind resistance. A horizontal short-circuit airlock, namely a self-sealing horizontal louver airlock, can be added to the original ventilation system. By setting this airlock, the resistance when the fan is connected to the grid during the original "stop-and-reverse" mode can be reduced, and the success rate of the fan motor starting can be improved by reducing the starting wind resistance of the fan.

2. The standby fan transitions from cold standby to hot standby to ensure the success rate of reversing

In order to further overcome the uncertainty of whether the standby ventilation fan can start normally under the traditional "stop-and-reverse" method, the standby ventilation fan is started without stopping the original operating ventilation fan. If it can start normally, reliable hot standby can be achieved; if a problem occurs that causes it to fail to start, the reversing operation can be paused to check and repair the fault. Because the actual reversing process has not yet begun, it will not affect the normal operation of the original fan on the grid. Therefore, the transition of the ventilation fan from cold standby to hot standby further improves the success rate of reversing.

3. Utilizing airlock switching to effectively supply underground ventilation power during the reversing process through the control system

In order to eliminate the safety hazard of short-term wind stoppage in the ventilation system during the reversing process of the ventilation fan in the existing "stop-and-reverse" mode, this system adopts a new "non-stop reversing" mode for the main coal mine ventilation fan. The most prominent feature of this reversing mode is that it achieves effective supply of ventilation power during the reversing process, thus providing effective protection for the non-stop wind during the downtime of the coal mine main ventilation fan. The airflow switching is an important process in the reversing process, and the airflow switching of the non-stop reversing system is completed by the joint action of two self-sealing horizontal louver airlocks and two electric side-opening (vertical airlocks can also be used if space is limited) airlocks, which is quick and flexible, and cooperates with the control system to achieve ventilation stability during the downtime of the ventilation fan, eliminating the problem of methane exceeding limits during downtime. Combining the characteristics of the main fan ventilation fans currently used in domestic mines, a non-stop reversing process is specially designed and implemented through an automatic control system.

III. Detailed Introduction of the Mine Main Fan Non-Stop Reversing System

System Composition

The mine main fan non-stop reversing system consists of two major parts: the non-stop reversing monitoring and control system and the non-stop reversing execution system:

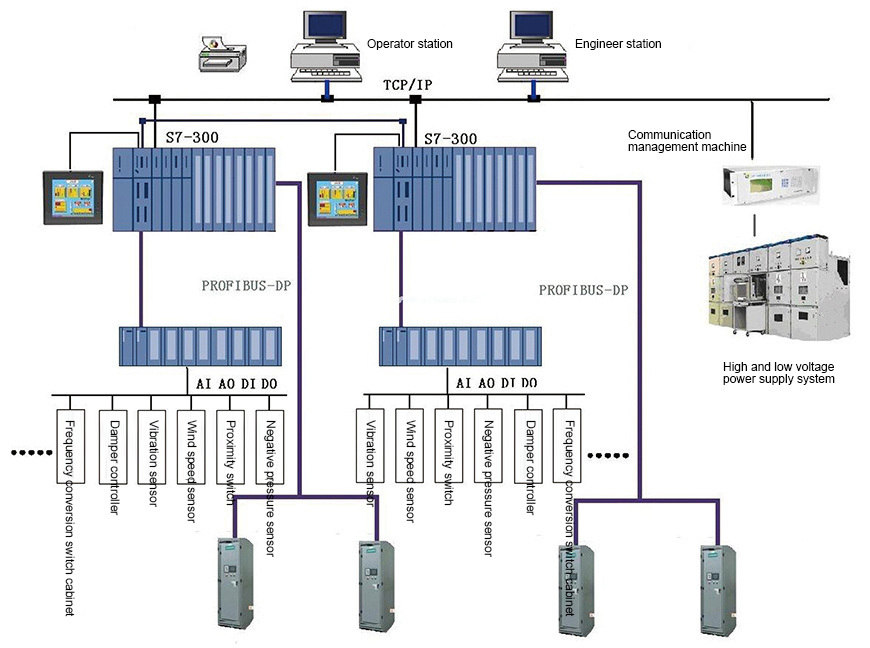

● Non-stop reversing monitoring and control system

The non-stop reversing monitoring and control system uses a high-end Siemens PLC and industrial control computer as its core, and is equipped with a fan fault expert system and hot standby reversing software program specially developed for non-stop reversing, as well as sensors (transmitters), signal acquisition devices, communication devices, and output and display devices.

● Non-stop reversing execution system

The uninterrupted wind-reversing system mainly consists of multiple functional wind gates and execution power units, also known as: anti-air short-circuit wind gates and vertical hanging-net adjusting wind gates, which are installed in the mine's ventilation roadway. For easy maintenance, another normally open backup wind gate can be added in front of the vertical adjusting wind gate on the side closer to the shaft.

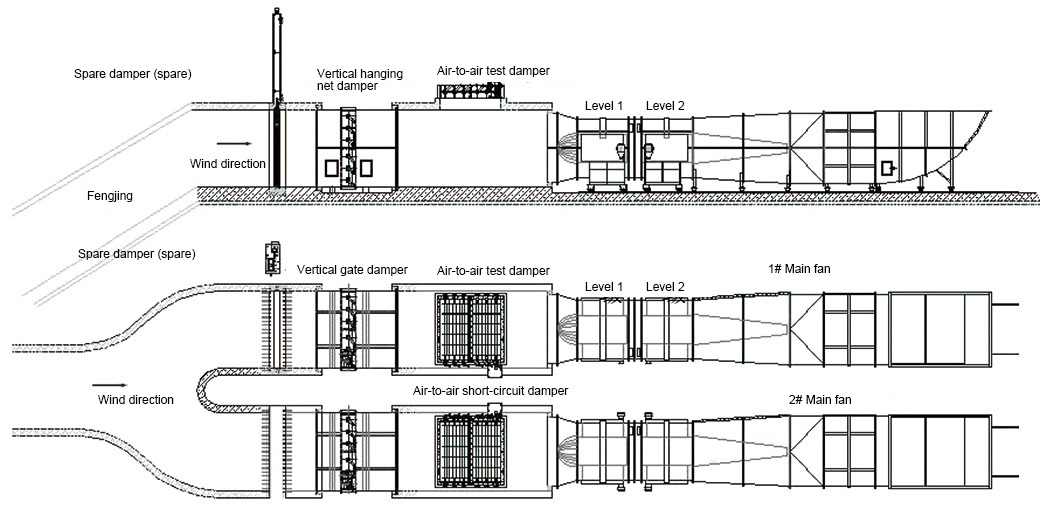

▲ Schematic diagram of the uninterrupted wind-reversing mechanical system

I. "One-button" reversing: Adopting a dual-machine hot backup mode and optimizing the control system to achieve "one-button" switching control of two fans without stopping the underground ventilation power.

II. Automatic reversing in case of failure: In the event of a fault and shutdown, the system prompts the operator to perform operations and has an automatic reversing function in case of failure.

III. Complete monitoring functions (online monitoring implementation):

● Real-time online monitoring of the fan motor's operating status and the wind gate's opening and closing status;

● Real-time monitoring and display of the fan's inlet static pressure, air volume, air speed signals, inlet temperature, and fan efficiency;

● Monitoring and performance analysis of fan voltage, current (power frequency current and variable frequency current), variable frequency frequency, power, and power factor, etc.;

● Online monitoring of the fan motor's bearing temperature and stator temperature, and it has an overlimit alarm function;

● Monitoring, display, and analysis of fan vibration status information;

● Real-time graphical curve display of online measured and processed fan operating parameters;

● Historical graphical curve display of measured and processed fan operating parameters, and the ability to query historical data at any time;

● Query and display of online measured and processed fan historical operating data in report form, and it can retrieve monitoring data from the past two years of the fan;

● Realize over-limit alarms for online measured and processed fan operating parameters in various forms:

◇ The parameters on the main monitoring screen are displayed in red;

◇ Alarm lights flash to indicate;

◇ Audible alarm prompt.

● Realize unmanned operation.

IV. Automated performance testing: Adjust the air volume and pressure through the control system, automatically collect data, and perform automated performance testing.

● Control the opening, closing, and stopping of the fan wind gate, adjust the wind gate to any angle (0 degrees to 90 degrees), and keep the fan at a certain negative pressure point;

● According to the fan performance testing requirements and the negative pressure range of the fan, the system can automatically adjust the wind gate to obtain the negative pressure at each measuring point;

● Record the operating parameters of the measuring points (air volume, negative pressure, power, current, vibration, efficiency), generate reports, and draw fan performance curves.

V. Fault diagnosis: Establish an expert system that can correctly judge and output alarm signals and automatic diagnostic conclusions when abnormal conditions occur during fan operation.

● Fault diagnosis of the motor's bearing temperature and stator temperature;

● Fault diagnosis of the fan's horizontal and vertical vibrations;

● Fault diagnosis of the fan's sudden increase and decrease in air volume;

● Overlimit diagnosis of the methane concentration at the fan inlet.

VI. Remote communication function: Supports remote monitoring with third-party remote devices (inverters or other control devices). Supports multiple communication protocols, such as Modbus and OPC, and has multiple communication schemes. It can easily upload monitoring data to the integrated automation system currently used in coal mines to achieve integration of the coal mine information system.

Working principle of the uninterrupted wind-reversing system

I. According to the starting characteristics of the ventilation fan, the magnitude and duration of the starting current are related to the wind resistance. As shown in Figure 1, adding a horizontal adjustable anti-air short-circuit wind gate to the original ventilation system can reduce the resistance during fan startup in the original "shutdown and reversal" mode, reduce the fan starting wind resistance, and improve the success rate of fan motor starting.

In order to further overcome the uncertainty of whether the backup ventilation fan can start normally in the traditional "shutdown and reversal" mode, the project adopts hot standby before reversing the coal mine ventilation fan. Under the premise that the original running fan does not stop, the backup fan is started. After normal startup, reliable hot standby can be achieved; if a problem occurs that prevents startup, the reversing operation can be paused to troubleshoot and repair the fault, because the actual reversing process has not yet started, it will not affect the normal operation of the original fan. Therefore, the transition of the ventilation fan from cold standby to hot standby further improves the success rate of reversing.

II. In order to eliminate the safety hazard of system wind stoppage during the fan reversing process in the existing "shutdown and reversal" mode, the new coal mine main ventilation fan "uninterrupted wind-reversing" mode used in this system is characterized by effective supply of ventilation power during the reversing process, thus providing effective protection for the uninterrupted wind supply during the reversing of the coal mine main ventilation fan; the wind path switching is completed by the combined action of four wind gates, and using its fast and flexible switching characteristics, through certain control strategies, this system effectively achieves ventilation stability during fan reversing, thereby preventing the problem of exceeding the methane limit during reversing. The system combines the characteristics of main fan ventilation fans currently used in domestic mines, specifically designed the uninterrupted wind-reversing process, and implemented it through an automatic control execution system (in conjunction with Figure 1):

● When fan No. 1 is operating normally, open the No. 2 horizontal anti-air short-circuit wind gate and start the backup fan No. 2. (At this time, the fan is in idle operation, which means that the airflow enters from the horizontal short-circuit wind gate window and exits from the outlet, achieving hot standby before starting.)

● After checking (control system self-check) that the backup fan No. 2 is running normally, open the No. 1 horizontal anti-air short-circuit wind gate and close the No. 1 vertical hanging-net wind gate at the same time, so that the original running fan No. 1 transitions to idle operation.

● Open the No. 2 vertical hanging-net wind gate next to the running backup fan No. 2 and close the No. 2 horizontal anti-air short-circuit wind gate at the same time, so that it transitions to the normal operating state with the underground ventilation network.

● After checking that the backup fan is running normally on the network, stop the original running fan, and the reversing is complete.

In addition, the system automatically identifies ventilation equipment operation failures that may lead to sudden stoppages and serious consequences during the operation of the main ventilation equipment in coal mines. It ensures switching to backup ventilation equipment within one minute, effectively curbing the expansion of ventilation system accidents caused by ventilation equipment failures.

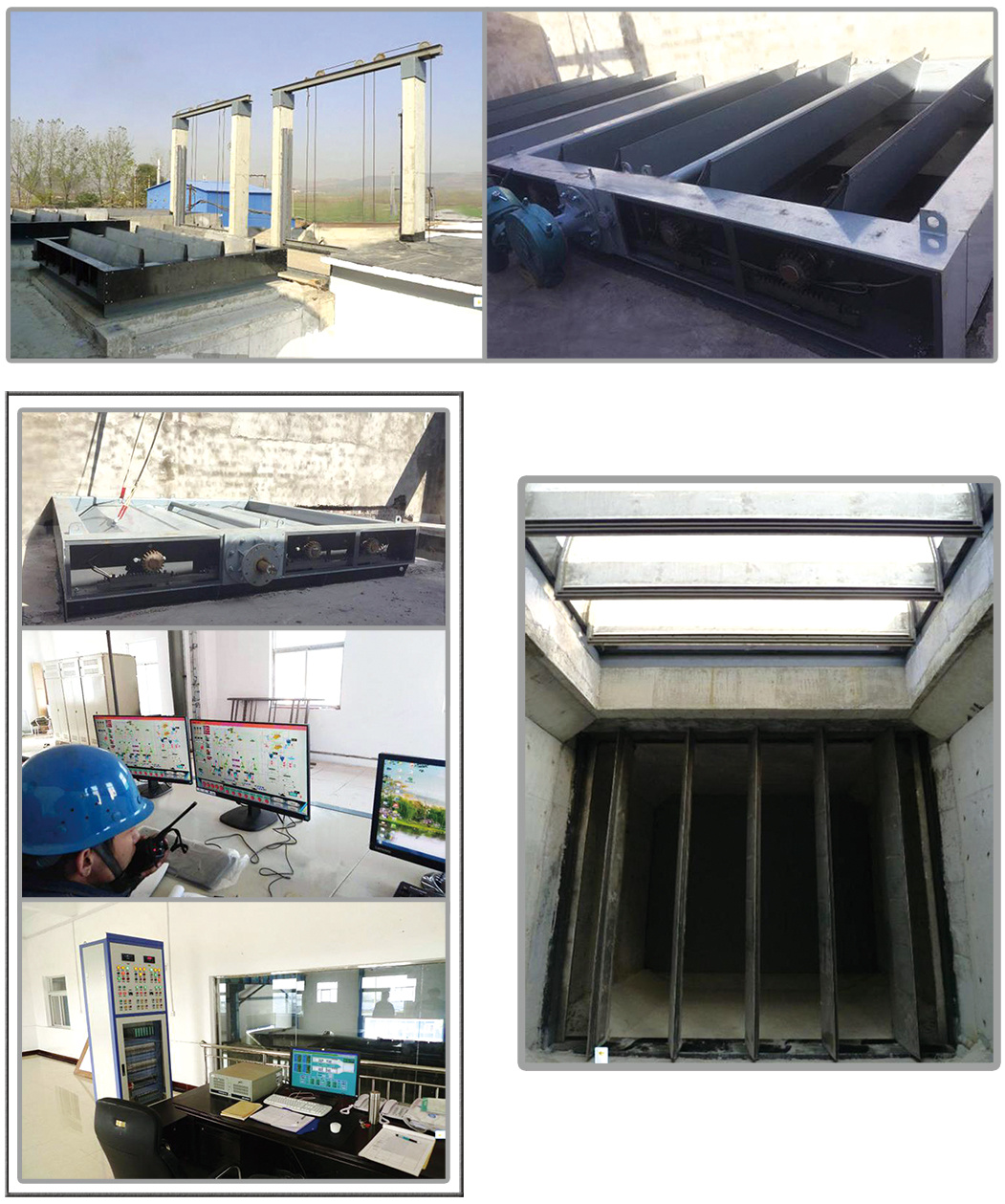

On-site reference image

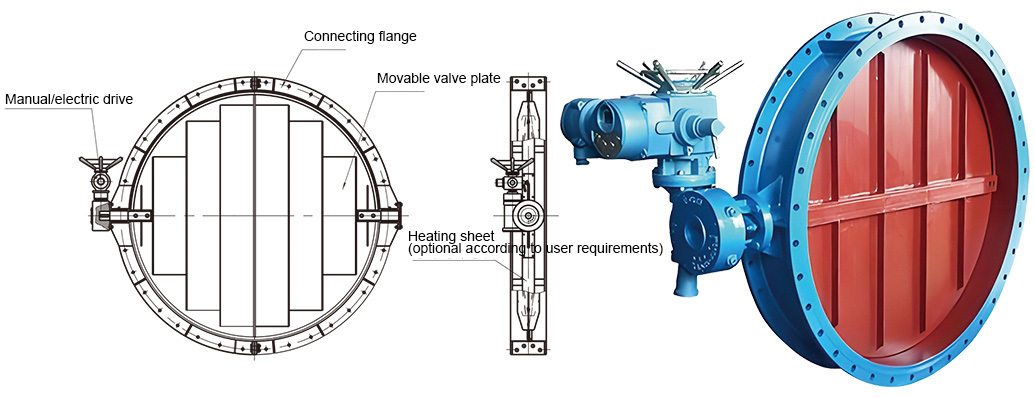

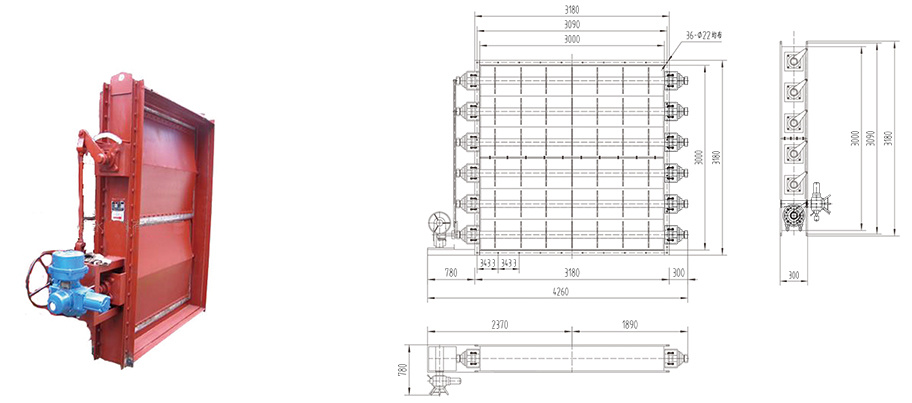

Mine Ventilation Butterfly Valve D941W-1C

The mine ventilation butterfly valve is specially designed by our company for axial flow fans.

I. Structural Features

The mine ventilation butterfly valve is welded using high-quality steel. It features a reasonable structure, wear resistance, low flow resistance loss, flexible operation, clear indication of direction, easy maintenance, and a long service life. It can be installed horizontally or vertically. Equipped with QAW electric devices and related accessories, it can achieve manual and electric interference-free switching, microcomputer program control, electric control or central centralized control, making it an ideal equipment for automated control operation and flow regulation.

II. Working Principle

The mine ventilation butterfly valve mainly consists of a valve body, butterfly plate, valve shaft, electric device, and other parts. When the electric device receives a control signal from the transducer or a manual signal from the operator, it transmits power to the valve shaft through the output angular displacement, driving the butterfly plate to rotate synchronously to achieve full opening, full closure, and arbitrary adjustment. The electric device synchronizes the feedback signal with the opening degree of the butterfly plate. Users can control the arbitrary opening of the butterfly plate according to the signal, or they can achieve full opening, full closure, and arbitrary adjustment manually. If the ambient temperature is too low, an electric heating system can be equipped to prevent the valve from freezing and jamming, ensuring the normal operation of the equipment.

D941W-1C Outline Drawing

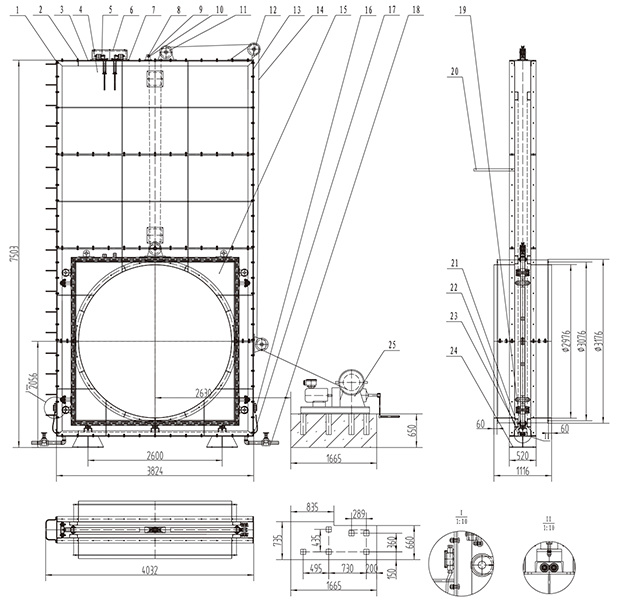

Electric Louver Damper

Function Introduction

Electric louver dampers are mainly used for intercepting air and flue gas in the air ducts of power plant boiler smoke and wind passages, coal mines, cement plants, and copper smelting ventilation systems. They have full opening and closing functions and are generally not used for regulating air volume and pressure head. They are usually installed at the inlet and outlet pipes of the air preheater's flue gas and air chamber; the inlet and outlet flues of the dust collector and induced draft fan; the suction duct and outlet pipe of the blower and primary air fan; and the primary and secondary air ducts before the coal mill inlet. In coal mine ventilation systems, they are usually used to intercept air in the air ducts before and after the shaft mouth fan. The structure is lightweight, the opening and closing rotation is flexible during operation, the driving force is short, the sealing performance is good, and it can withstand the working pressure and temperature in the air duct. The full pressure switch time is less than 40 seconds.

Structure and Principle

The electric louver damper consists of an outer frame, damper blades, sealing strips, front and rear shafts, drive shaft, bearings, shaft seal, crank, connecting rod, and actuator. The outer frame is made of hot-rolled channel steel or steel plate, which is integrally stamped and welded. Large-size frames are connected by tension rods. The damper blades are designed in an airfoil shape to minimize flow resistance and wear in dusty airflow. To prevent deformation after welding, the damper blades are not welded but connected using support plates and support tubes. The support plates are connected to the damper blades by bolts at both ends, and the flatness of the damper blades is adjusted by adjusting the nuts at both ends of the support plates. The blades can be easily replaced without removing the frame after wear. A stainless-steel elastic sealing strip is embedded between the inner side of the frame and the damper blades, sealed by the pressure difference of the airflow on both sides of the damper. The damper shafts are connected to the intermediate support arms of the blades with positioning bolts. After the damper shafts extend out of the frame, they are connected to the crank with a key, and the journal is sealed with packing. They are connected by a drive shaft to drive the device to make a 90-degree full opening and closing rotation. The crank and connecting rod are integrally designed. The connecting rod adopts a double connecting rod, with adjustable length adjustment bolts at both ends and snap caps, which can adjust the sealing between each damper blade. UCFU self-aligning bearings are used for the front and rear damper shafts. This bearing has a small torque, self-lubrication, and requires no oiling, and allows for shaft expansion.

The damper frame is installed on the air duct, and any parts can be installed and removed on top, ensuring convenient inspection and replacement of bearings and packing in the working state. The frame wing surface is welded to the smoke and wind duct interface frame or flange surface after contact, or connected with bolts. The electric actuator can be directly installed on the damper body and connected directly to the main drive shaft through the actuator base, or connected through the drive shaft, connecting rod, and rocker arm. The electric actuator is installed on the platform or on-site.

Electric Box-Type Damper

Function Introduction

The structure, performance, and characteristics of the electric box-type damper are based on advanced foreign technologies and experience gained during the design and operation of similar domestic products. This product is mainly used to intercept air in the air ducts before and after the shaft fans in mine ventilation systems. It has full opening and closing functions, but cannot be used to regulate air volume. The structure is lightweight, with good sealing performance, flexible operation, accurate positioning, low fluid resistance, easy opening and closing, unrestricted media flow direction, and easy maintenance. It can also be operated remotely.

Structure and Principle

The electric box-type damper is welded from high-quality steel and mainly consists of a frame, gate plate, pulley, electric winch (or damper winch), and limit switch. It features a scientifically reasonable structure, flexible operation, pollution-free transmission parts, convenient maintenance, and a long service life. To prevent leakage during the opening and closing of the damper, the outer frame is fully enclosed.

When the electric box-type damper opens, the electric winch drives the steel rope through the pulley to make the gate plate connected to it overcome its own weight and move vertically upwards, opening the gate. When the gate opens to a certain position, it will trigger the limit switch to cut off the power of the winch and stop the movement, achieving safe opening. The opening position can be set by the user. Conversely, when the winch moves in the reverse direction, the gate plate moves vertically downwards under the action of gravity. When the gate closes to a certain position, it will trigger the limit switch to cut off the power of the winch and stop the movement, achieving safe closing. The closing position can be set by the user. If the ambient temperature is too low, an electric heating system can be equipped to prevent the valve from freezing and jamming, ensuring the normal operation of the equipment. To save costs, users can use an electric winch or consider replacing it with a manual mechanism.

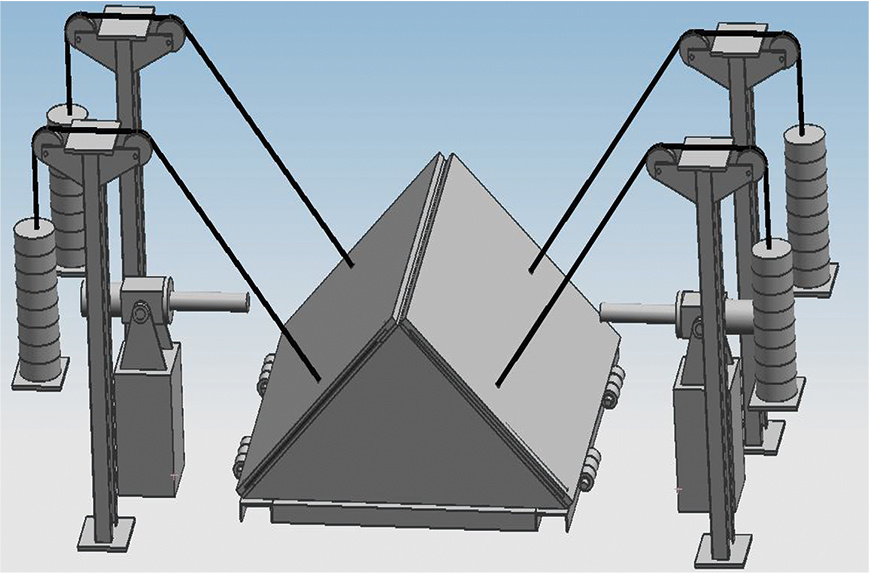

Self-Resetting Dry Vertical Shaft Explosion-Proof Door

The explosion-proof door is a special sealed well cover installed at the wellhead of the exhaust vertical shaft equipped with the main ventilation equipment in coal mines.

I. Function of the Explosion-Proof Door

1. Under normal ventilation, the explosion-proof door maintains airtightness, isolating the underground airflow from the ground atmosphere, preventing short-circuiting of airflow, and ensuring normal ventilation system operation.

2. When a gas or coal dust explosion occurs underground, the explosion-proof door is opened by the shock wave of the explosion airflow, allowing the explosion airflow to be directly discharged into the ground atmosphere, reducing the pressure of the airflow in the mine, playing a pressure-relief role, and preventing damage to the main ventilation fan caused by the explosion airflow impact.

3. When a fire occurs in the intake roadway or toxic gases exist, to prevent flames and toxic gases from entering the mining area and endangering the lives of miners, it is necessary to promptly reverse the airflow for fire extinguishing, which requires promptly pressing the explosion-proof door and using a positive pressure method to forcibly implement reverse airflow underground.

4. When the main ventilation fan stops running, the explosion-proof door can be opened to utilize natural wind pressure ventilation, maximizing the provision of fresh air underground to ensure the needs of underground personnel.

5. For a small number of coal mines using a single-duct ventilation system on the ground, due to the lack of a standby air duct for the three-yearly ventilation fan performance test, the mine needs to shut down, and the explosion-proof door is opened as a temporary air intake for the performance test, which is closed again after the test.

II. Existing Defects of Explosion-Proof Doors

1. The explosion-proof door cannot be reset or is difficult to reset.

2. Locking the explosion-proof door takes a long time and requires many personnel.

3. The explosion-proof door cannot be raised and lowered smoothly and synchronously.

4. The vertical shaft explosion-proof doors currently used in the mining area have varying degrees of air leakage.

5. The sealing liquid easily evaporates, causing serious air leakage.

6. It cannot be automatically closed and needs to be manually closed, which is slow and affects the normal operation of the ventilation system.

7. In multi-shaft coal mines, if the explosion-proof door cannot automatically reset after opening for pressure relief, the service areas of other shafts will be endangered by the explosion.

III. Advantages of Self-Resetting Dry Explosion-Proof Doors

1. After a gas explosion, the explosion-proof door can be reset in time to ensure the normal operation of the underground ventilation system.

2. The explosion-proof door structure is tight and airtight.

3. The structure of the explosion-proof door has sufficient strength and anti-ejection facilities.

4. The explosion-proof door is kept closed by the negative pressure of the ventilation fan and is equipped with a counterweight for easy opening.

5. During reverse airflow, the explosion-proof door is locked in the shortest time to meet the requirement of reverse airflow in the roadway within 10 minutes.

6. An early warning sensor is installed at least 500m in front of the roadway where the explosion-proof door is installed to open the explosion-proof door in advance of a gas explosion to reduce the impact of the explosion airflow on the explosion-proof door.

IV. Working Principle and Process

This design fundamentally solves the problem of opening and resetting the explosion-proof door after a gas explosion, eliminates safety hazards of ventilation system ancillary facilities, and ensures safe coal mine production. Its structural principle is:

The circular trough of the outlet is made square, and the existing explosion-proof door (cover) is changed to a hinged structure, with the shaft on the side and closure in the middle. A steel frame is installed at the outlet of the exhaust shaft. The structure of the door frame is square, with the explosion-proof door installed on the door frame. The explosion-proof door is a plate-type structure, with one leaf on each side, hinged to the door frame. The door leaf and door frame are sealed with a plate-type flexible rubber strip, and the sealing material forms a "口"-shaped sealing ring on the left and right door leaves. When the explosion-proof door is closed, the negative pressure in the mine causes the door leaf to adhere tightly to the door frame, forming a seal and preventing air leakage. This overcomes the problem of liquid evaporation and winter freezing of liquid sealing, with minimal seasonal impact on sealing and no need for liquid replenishment. The counterweight device is similar to the existing structure. The reverse airflow device consists of an electric push rod, and the rotational motion of the motor is converted into the linear motion of the push rod. The electric push rod body has a protection device. When the push rod moves to the limit position set by the limit switch or exceeds its rated push (pull) force, the electric push rod automatically stops, achieving overload protection, preventing damage to the device due to overload. The device can remotely control the explosion-proof door via cable. When reverse airflow is needed, the electric push rod is activated to hold the explosion-proof door, achieving locking. During normal operation, the electric push rod is closed, and the push rod retracts, realizing the explosion-proof function of the explosion-proof door. This allows the coal mine explosion-proof door (cover) to automatically reset after being opened by the impact wave of the explosion.

Normal operating state of the self-resetting dry vertical shaft explosion-proof door

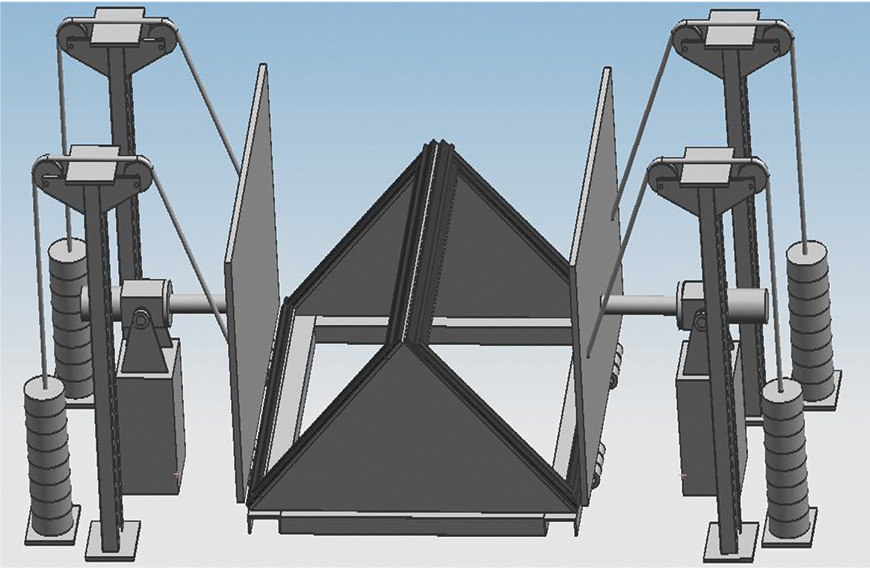

Working state of the explosion-proof door during reverse airflow

Explosion-proof cover open state when gas explosion occurs

Physical diagram of the self-resetting dry vertical shaft explosion-proof door

The company's main business is the design, research and development, and manufacturing of various ventilators and their supporting products for mines, non-coal mines, and rail transit. Products involve 38 series of fan products, more than 3,000 specifications, including FB(D) series, FBC(D)Z series, FKZ series, rail transit SDS series, tunnel SDF series, etc.; supporting products include shaft, inclined shaft self-resetting explosion-proof doors, louver-type automatic regulating air doors, side-opening (vertical) automatic regulating air doors, butterfly valves, silencers, main ventilator online detection and fault diagnosis systems, non-stop fan reverse systems and intelligent oil injection systems, which can fully meet the ventilation needs of mines and are sold to various domestic fields and international markets such as Russia and Canada.

In recent years, the company has successively won the honorary titles of "Yuncheng Enterprise Technology Center", "Yuncheng Excellent Enterprise", "Yuncheng Intellectual Property Demonstration Enterprise", and "Innovative Small and Medium-sized Enterprise". The company has passed the "ISO9001 Quality Management System Certification", "ISO14001 Environmental Management System Certification", "ISO45001 Occupational Health and Safety Management System Certification", and its products have passed the "China National Compulsory Product Certification". It has also obtained a number of patents. With advanced process equipment, strong technical strength, excellent product quality, and a perfect service system, it has won unanimous recognition and praise from users. In particular, the green, environmentally friendly, and low-noise fans that have been focused on the market in recent years have achieved rapid development, becoming a well-known enterprise in the fan industry with leading technology.

Previous Page:

Next Page:

Product Inquiry

*Please leave your phone number, we will contact you within 24 hours!