Product Categories

Contact Us

Email

sales@sxjyafan.com

Service Hotline:

+86-400-9944-001

Service Hotline:

+86-359-2480001

+86-13835937772

Energy-saving large-scale tunnel construction four-level (three-level) axial flow fan SDF(D4)(D3)

Wide variety, support customization, superior performance, worry-free after-sales service.Products can fully meet the ventilation needs of various scenarios such as mines and tunnels, and are exported to many different fields at home and abroad.

Products

Keywords:

Category:

Product Details

I. Overview

SDF series tunnel ventilation fans are suitable for tunnel construction ventilation in highway, railway and hydropower projects, and other underground engineering construction ventilation. Main products include SDF (A) type tunnel construction dedicated contra-rotating axial flow fan, SDF (B) type tunnel worker dedicated contra-rotating axial flow fan, SDF (C) type tunnel construction dedicated variable-speed contra-rotating axial flow fan, SDF (D4) Energy-saving long construction tunnel construction four-stage contra-rotating axial flow fan, SDF (E) New type tunnel dedicated axial flow fan, SDF (P) New type tunnel construction dedicated variable frequency energy-saving fan and other five series of hundreds of specifications of products.

II. Working Principle

The number of first and second level blades is different, and the distance between the two-stage impellers is very close. They rotate relatively, the first-stage impeller rotates clockwise, and the second-stage impeller rotates counterclockwise. After the first-stage impeller obtains energy, it directly enters the second-stage impeller to increase the pressure before discharging. The role of the second-stage impeller, in addition to increasing the airflow energy, also combines the function of the stationary guide vanes of other types of axial flow fans. While obtaining the guided straightening circumferential velocity component, it smooths the impact of the airflow, increases the energy of the airflow, and also reduces noise.

III. Structural Features

1. Impeller: The impellers of the fans manufactured by our company adopt an adjustable moving blade design, which can be adjusted according to different ventilation needs. It also meets the ventilation needs in plateau environments. Material: Steel, and it undergoes arc flame spraying treatment; its strength is 20 times that of ordinary materials, with advantages such as corrosion resistance and high strength.

2. Dynamic Balance Test: Our company has a ø2.0 dynamic balance test bench. All fans are tested before leaving the factory to ensure product quality.

3. Fan Noise and Vibration: Mufflers are installed at the inlet and outlet ends of the fan to meet the standard value stipulated in JB/T8690 "Noise Limits for Industrial Ventilation Fans"; the weighted A-level noise LSA≤25dB(A) at the optimal efficiency operating point; vibration is lower than the required vibration effective value (RMS) of 4.6mm/s stipulated in JB/T8689 "Ventilation Fan Vibration Detection and Its Limits".

4. Housing and other component materials: The housing adopts double-layer plate welding, with ultra-fine glass fiber cotton lining in the middle to achieve a good noise reduction effect. The fan is sturdy and durable, has a long service life, and has undergone strict surface treatment; the minimum design service life of the fan is not less than 15 years.

5. Fan manufacturing standards: The fans are strictly manufactured according to national standards and relevant industry standards.

6. The fan has the characteristics of compact structure, long air delivery distance, high efficiency, easy maintenance, and convenient repair.

7. The performance of the fan is strictly inspected before leaving the factory, and relevant certificates of conformity are provided.

Special Instructions

1. Instructions for use of high-altitude ultra-long tunnel ventilation fans

The SDF series tunnel ventilation fans produced by our company have adjustable installation angles and can be used for construction ventilation in high-altitude environments. When using, simply adjust to the corresponding installation angle under the altitude condition, which is simple to operate and convenient to use.

When the fan is used in plateau areas, due to the low atmospheric pressure, the air density at the fan's use site is lower than 1.2kg/m³, which makes the actual pressure of the fan lower than the value in the performance table. At this time, the calculation of the fan's performance is as follows:

Flow rate Q=Qo (m³/min)

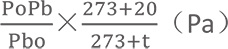

Pressure =

P o ——Pressure in the performance table (Pa)

P bo ——Standard atmospheric pressure 101235Pa

P b ——The relationship between the pressure at the fan use site and atmospheric pressure varies with altitude:

Where: H——Altitude, unit: km T——Temperature at the fan use site (°C)

2. When users select and use the fan, the diameter of the matching air duct must be larger than the impeller diameter. When selecting the air duct, it is best to use a flexible air duct, with a leakage rate ≤1%, to achieve the best effect. The fan outlet has a direct head that facilitates connection with the air duct (a variable diameter connector that meets the requirements can also be made according to user needs).

According to the construction situation, the manufacturer recommends using the following response diameter air ducts. (Note: It is forbidden to use steel ring negative pressure air ducts.)

|

Fan model |

Minimum selected diameter (mm) |

Optimal selected diameter (mm) |

Fan model |

Minimum selected diameter (mm) |

Optimal selected diameter (mm) |

|

|

SDF-No4.0 |

500 |

600 |

SDF-No11.5 |

1200 |

1300-1400 |

|

|

SDF-No5.0 |

550 |

600 |

SDF-No12.5 |

1400 |

1500-1800 |

|

|

SDF-No5.3 |

600 |

700 |

SDF-No13 |

1400 |

1500-1800 |

|

|

SDF-No5.6 |

600 |

700 |

SDF-No14 |

1500 |

1600-1800 |

|

|

SDF-No6.0 |

700 |

800 |

SDF-No15 |

1600 |

1700-1900 |

|

|

SDF-No6.5 |

700 |

800 |

SDF-No16 |

1800 |

1900-2200 |

|

|

SDF-No7.1 |

800 |

900 |

SDF-No17 |

1800 |

1900-2200 |

|

|

SDF-No7.5 |

800 |

900 |

SDF-No18 |

2000 |

2100-2400 |

|

|

SDF-No8.0 |

900 |

1000 |

SDF-No19 |

2100 |

2200-2400 |

|

|

SDF-No9.6 |

1000 |

1200-1300 |

SDF-No20 |

2200 |

2300-2500 |

|

|

SDF-No10 |

1200 |

1200-1300 |

SDF-No21 |

2300 |

2400-2600 |

|

|

SDF-No10.5 |

1200 |

1300-1400 |

SDF-No22 |

2400 |

2500-2700 |

|

|

SDF-No11 |

1200 |

1300-1400 |

SDF-No23 |

2500 |

2600-2800 |

3. According to user needs, non-standard fan design can also be carried out, providing optimized aerodynamic and structural design schemes to provide users with economical and reliable fans.

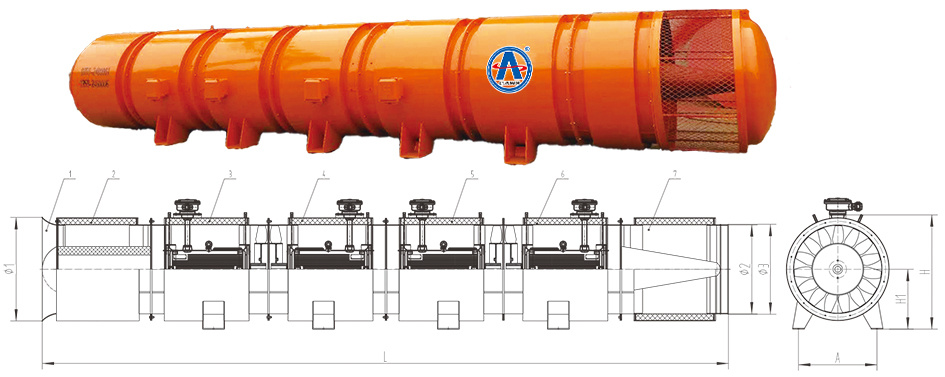

SDF(D4)(D3) Energy-saving Long and Large Tunnel Construction Four-stage (Three-stage) Axial Flow Fan

I. Scope of Application

SDF (D4)(D3) The energy-saving long and large tunnel construction four-stage (three-stage) axial flow fan is a fan specially designed for long and large tunnels after repeated experiments and research. It is suitable for long-distance and constant-volume ventilation during tunnel construction in highway, railway, and water diversion projects, and features long air delivery distance, low noise, high efficiency, and large air volume. It solves the problem that general axial flow fans cannot meet the air delivery requirements when the tunnel excavation distance is long.

SDF (D4)(D3) Each stage of the energy-saving long and large tunnel construction four-stage (three-stage) axial flow fan is driven by an electric motor with the same power. The impeller is directly connected to the motor, and the rotation directions of adjacent impellers are opposite. The airflow enters the first-stage impeller to obtain energy, is accelerated by the second-stage impeller, and then discharged after being accelerated by the subsequent impellers. The subsequent impellers also have the function of stationary guide vanes in ordinary axial flow fans. While obtaining the straightened circumferential velocity component, they increase the energy of the airflow, thus achieving higher air pressure and efficiency than bipolar counter-rotating fans.

For tunnel construction ventilation under special environments, various spray coatings can be applied to the blades according to user requirements.

SDF (D4)(D3) The energy-saving long and large tunnel construction four-stage (three-stage) axial flow fan is also suitable for ventilation needs in plateau environments.

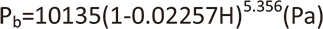

II. Model and Meaning

The ventilation model and its meaning are as follows: SDF (D4)(D3) Energy-saving long and large tunnel construction four-stage (three-stage) axial flow fan

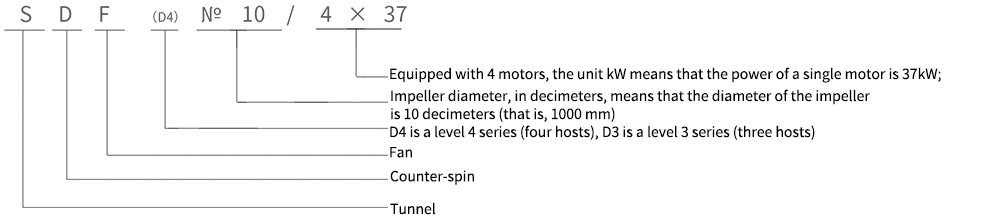

III. Structural Outline Diagram

Three-stage fan external structure diagram

1. Collector 2. Inlet silencer 3. Primary unit 4. Secondary unit 5. Tertiary unit 6. Outlet silencer

Four-stage fan external structure diagram

1. Collector 2. Inlet silencer 3. Primary unit 4. Secondary unit 5. Tertiary unit 6. Quaternary unit 7. Outlet silencer

IV. Technical Performance Parameters Table of High-speed Fan (Speed 2980r/min)

|

Model |

Matched Motor |

Power (kW) |

Air Volume (m³/min) |

Air Pressure (Pa) |

Φ1 |

Φ2 |

Φ3 |

L |

H |

H1 |

A |

|

N o 6.0 |

YE3-160M1-2 |

3×11 |

220~370 |

1000~5600 |

720 |

603 |

617 |

3520 |

802 |

405 |

540 |

|

YE3-160M2-2 |

3×15 |

300~400 |

1100~6300 |

720 |

603 |

617 |

3520 |

802 |

405 |

540 |

|

|

N o 6.0 |

YE3-160M1-2 |

4×11 |

220~370 |

1350~7500 |

720 |

603 |

617 |

4220 |

802 |

405 |

540 |

|

YE3-160M2-2 |

4×15 |

300~400 |

1500~8500 |

720 |

603 |

617 |

4220 |

802 |

405 |

540 |

|

|

N o 6.3 |

YE3-160L-2 |

3×18.5 |

350~550 |

1200~7200 |

760 |

634 |

650 |

3605 |

843 |

430 |

560 |

|

YE3-180M-2 |

3×22 |

380~600 |

1300~7500 |

760 |

634 |

650 |

3670 |

843 |

430 |

560 |

|

|

N o 6.3 |

YE3-160L-2 |

4×18.5 |

350~550 |

1550~9500 |

760 |

634 |

650 |

4190 |

843 |

430 |

560 |

|

YE3-180M-2 |

4×22 |

380~600 |

1600~10000 |

760 |

634 |

650 |

4305 |

843 |

430 |

560 |

|

|

N o 7.1 |

YE3-200L1-2 |

3×30 |

450~720 |

1200~8000 |

860 |

718 |

732 |

4050 |

947 |

476 |

560 |

|

YE3-200L2-2 |

3×37 |

530~820 |

1300~8600 |

860 |

718 |

732 |

4050 |

947 |

476 |

610 |

|

|

YE3-225M-2 |

3×45 |

530~850 |

1800~9000 |

860 |

718 |

732 |

4135 |

947 |

476 |

610 |

|

|

N o 7.1 |

YE3-200L1-2 |

4×30 |

470~780 |

1500~11000 |

860 |

718 |

732 |

4775 |

947 |

476 |

610 |

|

YE3-200L2-2 |

4×37 |

530~830 |

1800~12000 |

860 |

718 |

732 |

4775 |

947 |

476 |

610 |

|

|

YE3-225M-2 |

4×45 |

540~860 |

1600~12500 |

860 |

718 |

732 |

4860 |

947 |

476 |

610 |

|

|

N o 8.0 |

YE3-225M-2 |

3×45 |

600~880 |

2000~9200 |

960 |

804 |

820 |

4330 |

1033 |

535 |

650 |

|

YE3-250M-2 |

3×55 |

660~980 |

2200~9300 |

960 |

804 |

820 |

4645 |

1033 |

535 |

650 |

|

|

YE3-280S-2 |

3×75 |

700~1050 |

2500~9500 |

960 |

804 |

820 |

4825 |

1033 |

535 |

650 |

|

|

N o 8.0 |

YE3-225M-2 |

4×45 |

650~880 |

2500~9500 |

960 |

804 |

820 |

5076 |

1033 |

535 |

650 |

|

YE3-250M-2 |

4×55 |

700~1000 |

3000~12500 |

960 |

804 |

820 |

5496 |

1033 |

535 |

650 |

|

|

YE3-280S-2 |

4×75 |

750~1100 |

4000~13500 |

960 |

804 |

820 |

5736 |

1033 |

535 |

650 |

V. Fan Performance Parameters Table (Four-stage Fan)

|

Fan model |

Power (kW) |

Air Volume (m³/min) |

Air Pressure (Pa) |

Speed (r/min) |

|

SDF (D4) -N o 9.6 |

4×30 |

680~1325 |

1000~6400 |

1480 |

|

SDF (D4) -N o 10 |

4×37 |

770~1500 |

1100~7000 |

1480 |

|

SDF (D4) -N o 10.5 |

4×45 |

891~1736 |

1182~7720 |

1480 |

|

SDF (D4) -N o 11 |

4×55 |

1015~1985 |

1200~8300 |

1480 |

|

SDF (D4) -N o 11.5 |

4×75 |

1170~2285 |

1450~9250 |

1480 |

|

SDF (D4) -N o 12.5 |

4×110 |

1550~2912 |

1720~10700 |

1480 |

|

SDF (D4) -N o 13 |

4×132 |

1695~3300 |

1860~12000 |

1480 |

|

SDF (D4) -N o 14 |

4×185 |

2113~4116 |

2156~13700 |

1480 |

|

SDF (D4) -N o 14 |

4×75 |

1399~3013 |

946~6400 |

980 |

|

SDF (D4) -N o 15 |

4×90 |

1721~3760 |

1086~7120 |

980 |

|

SDF (D4) -N o 16 |

4×110 |

2088~4500 |

1236~8100 |

980 |

|

SDF (D4) -N o 17 |

4×160 |

2505~5100 |

1394~9142 |

980 |

|

SDF (D4) -N o 18 |

4×185 |

2649~4479 |

1464~10510 |

980 |

|

4×200 |

2962~5100 |

1904~11018 |

||

|

4×250 |

3302~5748 |

2456~11674 |

||

|

4×280 |

3643~6312 |

2916~12136 |

||

|

4×315 |

3935~6772 |

3118~12728 |

||

|

SDF (D4) -N o 19 |

4×220 |

3115~5268 |

1632~11710 |

980 |

|

4×250 |

3438~5998 |

2121~12278 |

||

|

4×315 |

3884~6760 |

2736~13007 |

||

|

4×355 |

4284~7424 |

3248~13562 |

||

|

4×400 |

4629~7965 |

3474~14182 |

||

|

SDF (D4) -N o 20 |

4×280 |

3663~6144 |

1801~12974 |

980 |

|

4×355 |

4063~6996 |

2350~13604 |

||

|

4×400 |

4530~7885 |

3032~14412 |

||

|

4×450 |

4997~8659 |

3600~15028 |

||

|

4×500 |

5398~9290 |

3850~15714 |

||

|

SDF (D4) -N o 21 |

4×355 |

4206~7112 |

1992~14302 |

980 |

|

4×450 |

4704~8099 |

2590~14998 |

||

|

4×500 |

5244~9128 |

3342~15890 |

||

|

4×560 |

5785~10024 |

3968~16568 |

||

|

4×630 |

6249~10313 |

4244~17324 |

||

|

SDF (D4) -N o 22 |

4×450 |

4836~8178 |

2186~15698 |

980 |

|

4×560 |

5408~9312 |

2844~16460 |

||

|

4×630 |

6030~10495 |

3668~17440 |

||

|

4×710 |

6651~11525 |

4356~18182 |

||

|

4×800 |

7185~12365 |

4658~19012 |

||

|

SDF (D4) -N o 23 |

4×560 |

5525~9344 |

2390~17158 |

980 |

|

4×710 |

6180~10640 |

3108~17992 |

||

|

4×800 |

6890~11992 |

4008~19060 |

||

|

4×900 |

7600~13169 |

4760~19874 |

||

|

4×1000 |

8210~14129 |

5092~20780 |

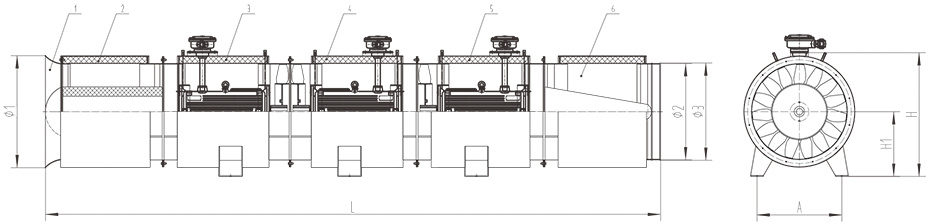

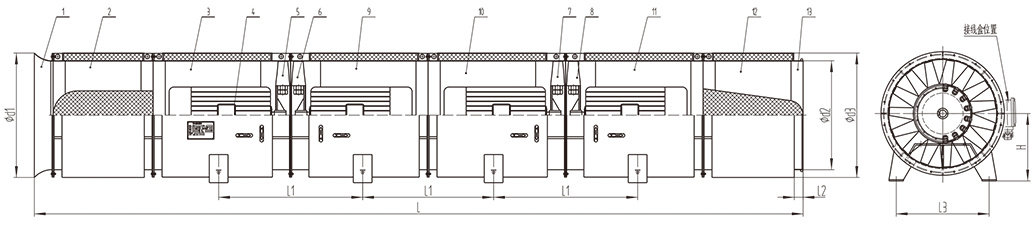

VI. Structural Diagram

1. Current collector 2. Intake silencer 3. Main unit (1) 4. Motor 5. First-stage impeller 6. Second-stage impeller 7. Third-stage impeller

VII. External Dimensions

|

Fan model |

L |

L1 |

L2 |

L3 |

H |

d1 |

d2 |

d3 |

N-Ø |

Weight (kg) |

|

SDF (D4) -N o 9.6 |

5932 |

895 |

200 |

685 |

640 |

1152 |

966 |

1142 |

16-Ø16 |

5000 |

|

SDF (D4) -N o 10 |

7010 |

1065 |

220 |

704 |

660 |

1220 |

1006 |

1182 |

16-Ø16 |

5700 |

|

SDF (D4) -N o 10.5 |

7230 |

1065 |

220 |

704 |

680 |

1270 |

1056 |

1234 |

16-Ø16 |

6800 |

|

SDF (D4) -N o 11 |

8022 |

1265 |

220 |

775 |

750 |

1328 |

1108 |

1284 |

20-Ø16 |

7850 |

|

SDF (D4) -N o 11.5 |

8050 |

1265 |

220 |

810 |

760 |

1380 |

1158 |

1334 |

20-Ø16 |

9850 |

|

SDF (D4) -N o 12.5 |

8986 |

1420 |

220 |

884 |

856 |

1500 |

1258 |

1436 |

20-Ø18 |

10540 |

|

SDF (D4) -N o 13 |

9020 |

1420 |

220 |

884 |

856 |

1560 |

1308 |

1486 |

20-Ø18 |

11500 |

|

SDF(D4)-N o 14 |

9680 |

1590 |

220 |

926 |

920 |

1680 |

1408 |

1586 |

20-Ø18 |

11900 |

|

SDF (D4) -N o 15 |

10186 |

1618 |

220 |

1150 |

900 |

1720 |

1508 |

1690 |

20-Ø18 |

12400 |

|

SDF (D4) -N o 16 |

11040 |

1750 |

220 |

1066 |

970 |

1820 |

1608 |

1800 |

24-Ø18 |

12800 |

|

SDF (D4) -N o 17 |

11780 |

1860 |

220 |

1336 |

1010 |

1920 |

1708 |

1900 |

24-Ø18 |

14450 |

|

SDF (D4) -N o 18 |

12230 |

1923 |

220 |

1406 |

1054 |

2020 |

1808 |

1990 |

24-Ø18 |

|

|

SDF (D4) -N o 19 |

12950 |

2045 |

220 |

1484 |

1125 |

2132 |

1908 |

2090 |

24-Ø18 |

|

|

SDF (D4) -N o 20 |

13600 |

2150 |

220 |

1562 |

1195 |

2244 |

2008 |

2220 |

24-Ø18 |

- |

|

SDF (D4) -N o 21 |

14270 |

2260 |

220 |

1640 |

1248 |

2356 |

2110 |

2320 |

30-Ø18 |

- |

|

SDF (D4) -N o 22 |

14930 |

2365 |

220 |

1720 |

1300 |

2440 |

2210 |

2420 |

30-Ø18 |

- |

|

SDF (D4) -N o 23 |

15550 |

2475 |

220 |

1830 |

1360 |

2550 |

2310 |

2520 |

30-Ø18 |

- |

Note: If there are any changes to the fan's external dimensions, the dimensions provided at the time of ordering shall prevail.

The company's main business is the design, research and development, and manufacturing of various ventilators and their supporting products for mines, non-coal mines, and rail transit. Products involve 38 series of fan products, more than 3,000 specifications, including FB(D) series, FBC(D)Z series, FKZ series, rail transit SDS series, tunnel SDF series, etc.; supporting products include shaft, inclined shaft self-resetting explosion-proof doors, louver-type automatic regulating air doors, side-opening (vertical) automatic regulating air doors, butterfly valves, silencers, main ventilator online detection and fault diagnosis systems, non-stop fan reverse systems and intelligent oil injection systems, which can fully meet the ventilation needs of mines and are sold to various domestic fields and international markets such as Russia and Canada.

In recent years, the company has successively won the honorary titles of "Yuncheng Enterprise Technology Center", "Yuncheng Excellent Enterprise", "Yuncheng Intellectual Property Demonstration Enterprise", and "Innovative Small and Medium-sized Enterprise". The company has passed the "ISO9001 Quality Management System Certification", "ISO14001 Environmental Management System Certification", "ISO45001 Occupational Health and Safety Management System Certification", and its products have passed the "China National Compulsory Product Certification". It has also obtained a number of patents. With advanced process equipment, strong technical strength, excellent product quality, and a perfect service system, it has won unanimous recognition and praise from users. In particular, the green, environmentally friendly, and low-noise fans that have been focused on the market in recent years have achieved rapid development, becoming a well-known enterprise in the fan industry with leading technology.

Previous Page:

Next Page:

Product Inquiry

*Please leave your phone number, we will contact you within 24 hours!