Product Categories

Contact Us

Email

sales@sxjyafan.com

Service Hotline:

+86-400-9944-001

Service Hotline:

+86-359-2480001

+86-13835937772

SDS series tunnel ventilation fan

Wide variety, support customization, superior performance, worry-free after-sales service.Products can fully meet the ventilation needs of various scenarios such as mines and tunnels, and are exported to many different fields at home and abroad.

Products

Keywords:

Category:

Product Details

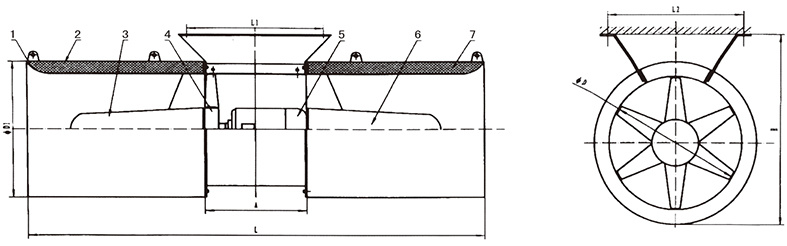

I. Diagram of Fan Structure

1. Collector 2. Inlet Silencer 3. Inlet Straightener 4. Impeller 5. Motor 6. Outlet Silencer 7. Outlet Straightener

II. Performance Parameters Table of the Radial Flow Fan

Appendix 1

|

Machine Number |

Motor Number of Poles |

Speed r/min |

Blade Angle |

Flow Rate m³/s |

Outlet Air Velocity m/s |

Axial Thrust N |

Motor Power kW |

Thrust/Power N/kW |

Sound Pressure Level dB(A) |

|

|

1D |

2D |

|||||||||

|

4 |

2P |

2840 |

D1 |

3.2 |

25.5 |

115 |

2.2 |

52.3 |

60 |

57 |

|

2840 |

D2 |

2.8 |

22.4 |

93 |

1.5 |

62 |

59 |

56 |

||

|

2830 |

D3 |

2.5 |

20.1 |

71 |

1.1 |

64.5 |

58 |

55 |

||

|

2830 |

D4 |

2.1 |

16.9 |

50 |

0.75 |

66.7 |

58 |

55 |

||

|

5 |

2P |

2900 |

D1 |

6.5 |

33.2 |

285 |

7.5 |

38 |

66 |

63 |

|

2900 |

D2 |

6 |

30.6 |

240 |

5.5 |

43.6 |

65 |

62 |

||

|

2890 |

D3 |

5.3 |

27.1 |

185 |

4 |

46.1 |

65 |

62 |

||

|

2840 |

D4 |

4.2 |

21.5 |

130 |

2.2 |

59.1 |

64 |

61 |

||

|

5.6 |

2P |

2930 |

D1 |

8.9 |

35.1 |

385 |

15 |

25.7 |

69 |

66 |

|

2930 |

D2 |

8.4 |

33.3 |

346 |

11 |

31.5 |

66 |

65 |

||

|

2900 |

D3 |

7.8 |

31.7 |

315 |

7.5 |

42 |

66 |

63 |

||

|

2900 |

D4 |

7 |

28.4 |

245 |

5.5 |

44.5 |

66 |

63 |

||

|

2890 |

D5 |

6.2 |

25.2 |

200 |

4 |

50 |

65 |

62 |

||

|

4P |

1400 |

D1 |

4.1 |

16.8 |

87 |

1.1 |

79.1 |

60 |

57 |

|

|

1400 |

D2 |

3.8 |

15.6 |

76 |

1.1 |

69.1 |

59 |

56 |

||

|

2/4P |

2930/1400 |

D1 |

8.4/4.1 |

33.3/16.8 |

346/76 |

12.5/8 |

31.5/29.1 |

60 |

65/57 |

|

|

2900/1400 |

D2 |

7.8/3.8 |

31.7/15.6 |

315/78 |

8.2 |

42/60.1 |

66/59 |

63/56 |

||

|

6.3 |

2P |

2950 |

D1 |

13.8 |

43.3 |

646 |

30 |

21.5 |

78 |

70 |

|

2940 |

D2 |

12.9 |

41.6 |

627 |

22 |

28.5 |

72 |

69 |

||

|

2930 |

D3 |

12.2 |

39.2 |

559 |

18.5 |

30.2 |

72 |

69 |

||

|

2930 |

D4 |

11.8 |

37.8 |

495 |

15 |

33 |

70 |

67 |

||

|

2930 |

D5 |

10.5 |

33.6 |

405 |

11 |

36.8 |

69 |

66 |

||

|

2900 |

D6 |

9.2 |

29.5 |

330 |

7.5 |

44 |

67 |

64 |

||

|

2900 |

D7 |

8.2 |

26.4 |

260 |

5.5 |

47.2 |

66 |

63 |

||

|

4P |

1430 |

D1 |

5.5 |

17.6 |

129 |

2.2 |

58.6 |

62 |

59 |

|

|

1400 |

D2 |

5 |

16.1 |

102 |

1.5 |

68 |

60 |

57 |

||

|

2/4P |

2930/1430 |

D1 |

11.8/5.5 |

37.8/17.6 |

495/129 |

16/3.8 |

33/58.6 |

70/62 |

67/59 |

|

|

2930/1400 |

D2 |

10.5/5.0 |

33.6/16.1 |

405/102 |

12.5/2.8 |

36.8/68 |

69/60 |

66/57 |

||

|

7.1 |

2P |

2950 |

D1 |

18 |

45.5 |

950 |

37 |

25.7 |

77 |

73 |

|

2950 |

D2 |

16.8 |

42.4 |

830 |

30 |

27.7 |

74 |

71 |

||

|

2940 |

D3 |

15.2 |

38.4 |

680 |

22 |

30.9 |

73 |

70 |

||

|

2930 |

D4 |

14.8 |

37.4 |

615 |

18.5 |

33.2 |

72 |

69 |

||

|

2930 |

D5 |

13.5 |

34.1 |

540 |

15 |

36 |

71 |

66 |

||

|

2900 |

D6 |

12.1 |

30.6 |

435 |

11 |

39.5 |

71 |

68 |

||

|

2900 |

D7 |

10.5 |

26.5 |

340 |

7.5 |

45.3 |

69 |

66 |

||

|

4P |

1400 |

D1 |

10.7 |

27.1 |

342 |

7.5 |

45.3 |

61 |

58 |

|

|

1400 |

D2 |

9.7 |

24.5 |

275 |

5.5 |

50 |

60 |

57 |

||

|

1430 |

D3 |

7.1 |

17.9 |

162 |

2.2 |

73.6 |

62 |

59 |

||

|

1400 |

D4 |

6.3 |

15.9 |

131 |

1.5 |

87.3 |

61 |

56 |

||

|

2/4P |

2930/1430 |

D1 |

14.8/7.1 |

37.4/17.9 |

615/162 |

18.5/2.2 |

33.2/73.6 |

72/62 |

69/59 |

|

|

2930/1430 |

D2 |

13.5/6.3 |

341/15.9 |

540/130 |

16/3.8 |

36/7.3 |

71/61 |

68/58 |

||

|

8 |

4P |

1470 |

D1 |

17.9 |

35.6 |

740 |

22 |

38 |

70 |

66 |

|

1470 |

D2 |

16.9 |

33.7 |

664 |

18.5 |

43.2 |

68 |

65 |

||

|

1460 |

D3 |

15.8 |

31.4 |

570 |

15 |

50 |

66 |

63 |

||

|

1460 |

D4 |

14.3 |

28.4 |

475 |

11 |

54.5 |

64 |

61 |

||

|

1440 |

D5 |

12.2 |

24.3 |

375 |

7.5 |

60 |

64 |

61 |

||

|

1440 |

D6 |

11 |

21.9 |

300 |

5.5 |

70 |

63 |

60 |

||

|

6P |

960 |

D1 |

10 |

19.9 |

240 |

4 |

60 |

61 |

56 |

|

|

960 |

D2 |

9.1 |

18.1 |

210 |

3 |

70 |

60 |

57 |

||

|

4/6P |

1460/960 |

D1 |

15.8/10 |

31.4/19.9 |

570/240 |

15.5/5.1 |

38/60 |

66/61 |

63/58 |

|

|

1460/960 |

D2 |

14.3/9.1 |

28.4/18.1 |

475/210 |

12/4 |

43.2/70 |

64/60 |

60/57 |

||

Appendix 2

|

Machine Number |

Motor Number of Poles |

Speed r/min |

Blade Angle |

Flow Rate m³/s |

Outlet Air Velocity m/s |

Axial Thrust N |

Motor Power kW |

Thrust/Power N/kW |

Sound Pressure Level dB(A) |

|

|

1D |

2D |

|||||||||

|

9 |

4P |

1480 |

D1 |

24.8 |

39 |

1125 |

37 |

30.4 |

73 |

69 |

|

1470 |

D2 |

23.2 |

36.4 |

885 |

30 |

32.8 |

72 |

68 |

||

|

1470 |

D3 |

21.1 |

33.1 |

805 |

22 |

36.6 |

70 |

67 |

||

|

1470 |

D4 |

19.8 |

31.2 |

735 |

18.5 |

39.7 |

68 |

65 |

||

|

1460 |

D5 |

18.5 |

29.1 |

600 |

15 |

40 |

66 |

63 |

||

|

1460 |

D6 |

16.7 |

26.3 |

512 |

11 |

46.5 |

64 |

61 |

||

|

1440 |

D7 |

14.2 |

22.3 |

410 |

7.5 |

54.7 |

63 |

60 |

||

|

6P |

970 |

D1 |

14.3 |

22.5 |

412 |

7.5 |

54.9 |

60 |

58 |

|

|

960 |

D2 |

12.4 |

19.5 |

315 |

5.5 |

57.3 |

60 |

57 |

||

|

4/6P |

1470/970 |

D1 |

21.1/13.8 |

33.1/21.7 |

805/410 |

24/8.5 |

36.6/50.7 |

70/60 |

67/58 |

|

|

1470/960 |

D2 |

19.8/12.4 |

31.2/19.5 |

735/315 |

18/6.2 |

39.2/57.3 |

68/60 |

65/57 |

||

|

10 |

4P |

1480 |

D1 |

30.5 |

38.8 |

1375 |

45 |

30.6 |

73 |

69 |

|

1480 |

D2 |

28.6 |

38.4 |

1215 |

37 |

32.8 |

71 |

67 |

||

|

1470 |

D3 |

27.6 |

35.1 |

1130 |

30 |

37.7 |

69 |

65 |

||

|

1470 |

D4 |

24.2 |

30.8 |

865 |

22 |

39.3 |

67 |

64 |

||

|

1470 |

D5 |

22.8 |

29.1 |

775 |

18.5 |

41.9 |

68 |

63 |

||

|

1460 |

D6 |

21.3 |

27.2 |

875 |

15 |

45 |

63 |

60 |

||

|

1460 |

D7 |

19.3 |

24.5 |

550 |

11 |

50 |

62 |

60 |

||

|

6P |

970 |

D1 |

21.3 |

27.2 |

675 |

15 |

45 |

63 |

60 |

|

|

970 |

D2 |

19.3 |

24.5 |

550 |

11 |

50 |

62 |

59 |

||

|

970 |

D3 |

14.8 |

18.8 |

440 |

7.5 |

58.7 |

61 |

58 |

||

|

4/6P |

1470/970 |

D1 |

27.6/19.3 |

35.1/24.5 |

1130/550 |

33/11 |

37.2/50 |

69/61 |

85/58 |

|

|

1470/970 |

D2 |

24.2/14.8 |

30.8/18.8 |

868/440 |

24/8.5 |

39.3/58.7 |

66/60 |

63/57 |

||

|

11.2 |

4P |

1480 |

D1 |

37.8 |

38.4 |

1690 |

55 |

30.7 |

74 |

70 |

|

1480 |

D2 |

35.6 |

36.1 |

1490 |

45 |

33.1 |

74 |

70 |

||

|

1480 |

D3 |

34.8 |

35.5 |

1370 |

37 |

37 |

71 |

68 |

||

|

1470 |

D4 |

31.1 |

32.6 |

1145 |

30 |

38.2 |

70 |

66 |

||

|

1470 |

D5 |

28.1 |

28.6 |

935 |

22 |

42.5 |

70 |

66 |

||

|

1470 |

D6 |

26.6 |

27.1 |

835 |

18.5 |

45.1 |

67 |

64 |

||

|

1460 |

D7 |

24.6 |

25 |

710 |

15 |

47.3 |

66 |

63 |

||

|

6P |

980 |

D1 |

31.2 |

31.7 |

1145 |

30 |

38.2 |

69 |

66 |

|

|

970 |

D2 |

28.2 |

28.6 |

935 |

22 |

42.5 |

67 |

64 |

||

|

970 |

D3 |

26.6 |

27.1 |

835 |

16.5 |

45.1 |

64 |

61 |

||

|

970 |

D3 |

24.8 |

25.2 |

715 |

15 |

48.7 |

63 |

60 |

||

|

970 |

D5 |

22.4 |

22.8 |

800 |

11 |

54.5 |

63 |

60 |

||

|

970 |

D6 |

19.5 |

20.2 |

465 |

7.5 |

62 |

62 |

59 |

||

|

4/6P |

1480/970 |

D1 |

34.8/22.4 |

31.5/22.8 |

1370/600 |

38/13 |

37/54.5 |

71/61 |

70/60 |

|

|

1480/970 |

D2 |

31.4/19.5 |

32.1/20.2 |

1145/465 |

33/11 |

36.2/62 |

70/60 |

66/59 |

||

Appendix 3

|

Machine Number |

Motor Number of Poles |

Speed r/min |

Blade Angle |

Flow m³s |

Outlet Air Velocity m/s |

Axial Thrust N |

Motor Power kW |

Thrust/Power N/kW |

Sound Pressure Level dB(A) |

|

|

1D |

2D |

|||||||||

|

12.5 |

4P |

1480 |

D1 |

48.5 |

39.5 |

2230 |

75 |

29.7 |

77 |

73 |

|

1480 |

D2 |

43.9 |

35.8 |

1830 |

55 |

33.3 |

75 |

71 |

||

|

1480 |

D3 |

42.4 |

34.6 |

1610 |

45 |

35.8 |

74 |

70 |

||

|

1480 |

D4 |

38.6 |

31.5 |

1420 |

37 |

38.4 |

73 |

69 |

||

|

1470 |

D5 |

36.1 |

29.4 |

1240 |

30 |

41.3 |

72 |

66 |

||

|

1470 |

D6 |

32.6 |

26.6 |

1010 |

22 |

45.9 |

70 |

66 |

||

|

1470 |

D7 |

30.8 |

25.1 |

900 |

18.5 |

48.6 |

69 |

65 |

||

|

6P |

980 |

D1 |

35.8 |

43.9 |

1835 |

55 |

33.4 |

73 |

69 |

|

|

980 |

D2 |

33.6 |

41.2 |

1610 |

45 |

35.8 |

72 |

68 |

||

|

980 |

D3 |

31.5 |

38.6 |

1420 |

37 |

38.4 |

70 |

66 |

||

|

980 |

D4 |

29.5 |

36.2 |

1240 |

30 |

41.3 |

68 |

64 |

||

|

970 |

D5 |

32.6 |

26.6 |

1010 |

22 |

45.9 |

66 |

62 |

||

|

970 |

D6 |

30.8 |

25.1 |

900 |

18.5 |

48.6 |

64 |

60 |

||

|

970 |

D7 |

27.2 |

22.2 |

785 |

15 |

52.3 |

63 |

59 |

||

|

970 |

D8 |

24.2 |

19.8 |

590 |

11 |

53.6 |

61 |

58 |

||

|

4/6P |

1480/970 |

D1 |

42.4/27.2 |

34.6/22.2 |

1610/785 |

47/16 |

35.8/52.3 |

74/63 |

70/59 |

|

|

1480/970 |

D2 |

38.6/24.2 |

31.5/19.8 |

1420/590 |

38/13 |

18.4/53.6 |

73/61 |

69/58 |

||

|

14 |

6P |

980 |

D1 |

42.2 |

27.4 |

1360 |

30 |

45.3 |

75 |

71 |

|

970 |

D2 |

37.6 |

24.4 |

1100 |

22 |

50 |

73 |

69 |

||

|

970 |

D3 |

32 |

20.8 |

840 |

15 |

56 |

71 |

67 |

||

|

970 |

D4 |

30.2 |

19.6 |

680 |

11 |

61.8 |

68 |

64 |

||

|

8P |

730 |

D1 |

31.4 |

20.4 |

770 |

15 |

51.3 |

71 |

67 |

|

|

730 |

D2 |

28.4 |

18.5 |

630 |

11 |

57.3 |

69 |

65 |

||

|

6/8P |

980/730 |

D1 |

42.4/31.4 |

27.4/20.4 |

1360/770 |

30/15 |

45.3/51.3 |

75/71 |

71/67 |

|

|

980/730 |

D2 |

37.6/28.4 |

24.4/18.5 |

1100/630 |

22/11 |

50.0/57.3 |

73/69 |

69/65 |

||

|

16 |

6P |

980 |

D1 |

63.8 |

31.9 |

2300 |

55 |

41.8 |

75 |

71 |

|

980 |

D2 |

57.8 |

28.8 |

1860 |

45 |

41.3 |

73 |

69 |

||

|

980 |

D3 |

50.6 |

25.2 |

1430 |

30 |

47.7 |

71 |

67 |

||

|

970 |

D4 |

46.1 |

22.9 |

1190 |

22 |

54.1 |

69 |

65 |

||

|

8P |

730 |

D1 |

47 |

23.4 |

1290 |

30 |

43 |

71 |

67 |

|

|

730 |

D2 |

42.6 |

21.2 |

1040 |

18.5 |

56.2 |

69 |

64 |

||

|

6/8P |

980/730 |

D1 |

63.8/42.6 |

31.9/21.2 |

2300/1290 |

55/28 |

41.8/46.1 |

75/71 |

71/67 |

|

|

980/730 |

D2 |

57.8/42.6 |

28.8/21.2 |

1860/1040 |

45/22 |

41.3/47.3 |

73/69 |

69/65 |

||

|

18 |

6P |

990 |

D1 |

83.6 |

32.9 |

3050 |

75 |

40.7 |

75 |

71 |

|

980 |

D2 |

74.6 |

29.3 |

2420 |

55 |

44 |

73 |

69 |

||

|

980 |

D3 |

63.4 |

24.9 |

1770 |

37 |

47.8 |

71 |

67 |

||

|

980 |

D4 |

60.2 |

23.7 |

1575 |

30 |

52.5 |

69 |

65 |

||

|

8P |

740 |

D1 |

62 |

24.4 |

1710 |

37 |

46.2 |

71 |

67 |

|

|

730 |

D2 |

55.1 |

21.7 |

1350 |

30 |

45 |

69 |

64 |

||

|

6/8P |

990/740 |

D1 |

83.6/62.0 |

32.9/24.4 |

3050/1710 |

75/37 |

40.7/46.2 |

75/71 |

71/67 |

|

|

980/730 |

D2 |

74.6/55.1 |

29.3/21.7 |

2420/1350 |

55/28 |

44.0/48.2 |

73/69 |

69/65 |

||

III. External Dimensions of SDS Series Fans

|

Fan Model |

L |

A |

D |

L 1 |

L 2 |

H |

Weight (kg) |

|

|

1D |

2D |

|||||||

|

SDS-No5.0 |

1450 |

2450 |

450 |

506 |

650 |

750 |

860 |

195 |

|

SDS-No6.3 |

1880 |

3140 |

620 |

636 |

750 |

940 |

1100 |

335 |

|

SDS-No7.1 |

2060 |

3480 |

640 |

716 |

800 |

1020 |

1200 |

365 |

|

SDS-No8.0 |

2310 |

3910 |

710 |

808 |

840 |

1100 |

1300 |

385 |

|

SDS-No9.0 |

2580 |

4390 |

780 |

908 |

940 |

1180 |

1400 |

455 |

|

SDS-No10.0 |

2890 |

4890 |

890 |

1008 |

1000 |

1260 |

1500 |

660 |

|

SDS-No11.2 |

3150 |

5390 |

910 |

1128 |

1100 |

1360 |

1620 |

730 |

|

SDS-No12.5 |

3410 |

5910 |

910 |

1260 |

1160 |

1470 |

1750 |

830 |

|

SDS-No14.0 |

3800 |

6600 |

1000 |

1410 |

1260 |

1740 |

2100 |

1080 |

|

SDS-No16.0 |

4400 |

7600 |

1200 |

1610 |

1360 |

1880 |

2300 |

1260 |

|

SDS-No18.0 |

4800 |

8400 |

1200 |

1810 |

1500 |

2050 |

2500 |

1475 |

IV. Installation, Operation, and Maintenance

1. When installing the jet fan, a pull-out test should be performed on the embedded parts during the early stage of tunnel construction, requiring it to withstand at least 15 times the weight of the fan. During the installation of the jet fan, the fan must not be bumped or damaged, and welding must not be performed on the fan. In addition to meeting the requirements of the tunnel clearance, the installation of the fan should ensure that the fan axis is parallel to the tunnel centerline; otherwise, it will increase the wind speed loss.

2. When starting the fan, check whether there are any foreign objects in the fan, whether the fan connecting bolts are loose, and whether the direction of rotation of the blade is consistent with the direction mark on the fan; to reduce the impact on the power grid, the fans should be started one by one, that is, one fan reaches the rated speed before the next one can be started; generally, there is a 120-second interval when starting directly; the operation control of the jet fan is generally determined by the CO concentration, whether to open one or a group, choose high speed or low speed; when the fan is reversed, the impeller must be completely stopped before the power supply is connected.

3. The fan does not require special maintenance. To keep the fan clean, the fan surface can be wiped regularly according to the pollution situation. For fans with oil injection holes, motor bearing lubricating oil should be added regularly. Refer to the "Motor Instruction Manual" for details; regularly clean the silencer mesh plate to prevent the mesh from being clogged by dust, which may affect the sound insulation effect.

The company's main business is the design, research and development, and manufacturing of various ventilators and their supporting products for mines, non-coal mines, and rail transit. Products involve 38 series of fan products, more than 3,000 specifications, including FB(D) series, FBC(D)Z series, FKZ series, rail transit SDS series, tunnel SDF series, etc.; supporting products include shaft, inclined shaft self-resetting explosion-proof doors, louver-type automatic regulating air doors, side-opening (vertical) automatic regulating air doors, butterfly valves, silencers, main ventilator online detection and fault diagnosis systems, non-stop fan reverse systems and intelligent oil injection systems, which can fully meet the ventilation needs of mines and are sold to various domestic fields and international markets such as Russia and Canada.

In recent years, the company has successively won the honorary titles of "Yuncheng Enterprise Technology Center", "Yuncheng Excellent Enterprise", "Yuncheng Intellectual Property Demonstration Enterprise", and "Innovative Small and Medium-sized Enterprise". The company has passed the "ISO9001 Quality Management System Certification", "ISO14001 Environmental Management System Certification", "ISO45001 Occupational Health and Safety Management System Certification", and its products have passed the "China National Compulsory Product Certification". It has also obtained a number of patents. With advanced process equipment, strong technical strength, excellent product quality, and a perfect service system, it has won unanimous recognition and praise from users. In particular, the green, environmentally friendly, and low-noise fans that have been focused on the market in recent years have achieved rapid development, becoming a well-known enterprise in the fan industry with leading technology.

Previous Page:

Next Page:

Product Inquiry

*Please leave your phone number, we will contact you within 24 hours!