Product Categories

Contact Us

Email

sales@sxjyafan.com

Service Hotline:

+86-400-9944-001

Service Hotline:

+86-359-2480001

+86-13835937772

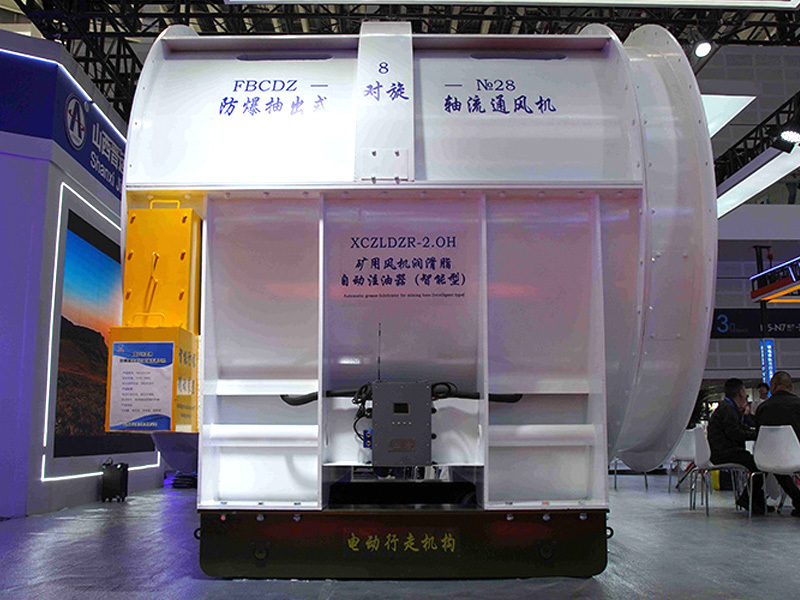

Intelligent lubricating grease automatic oiler for main mine ventilation fans

Wide variety, support customization, superior performance, worry-free after-sales service.Products can fully meet the ventilation needs of various scenarios such as mines and tunnels, and are exported to many different fields at home and abroad.

Products

Keywords:

Category:

Product Details

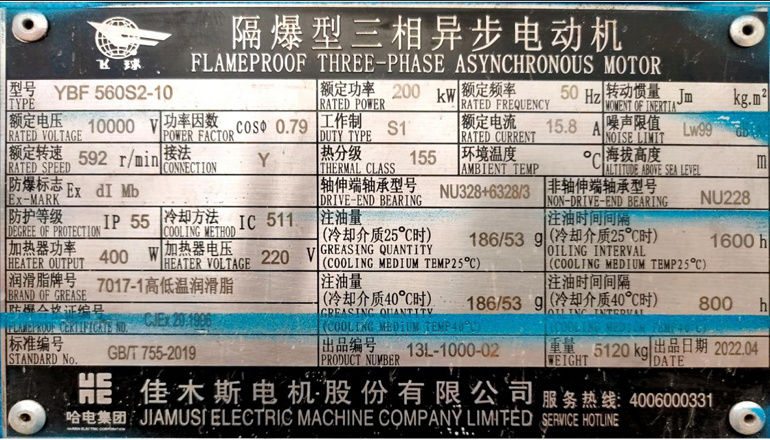

Currently, mine main ventilation fan motors typically use the YBF model. This motor uses two rows of bearings on the shaft extension end and one row on the non-shaft extension end. The front and rear bearings require different amounts of oil, with an approximate ratio of 2:1 or 3:1. Mine workers generally follow the factory's recommendations and manually add oil every 800-1600 hours to meet the lubrication requirements for normal motor operation. However, manual lubrication has several drawbacks: long intervals between lubrication, untimely lubrication, inaccurate measurement of lubrication amount, and particularly difficult oiling in northern winters. These factors can damage the motor bearings. To ensure the normal operation of ventilation equipment and address the issue of precise, timed oiling for main ventilation fan motors in any environment, an intelligent mine fan intelligent lubricating grease automatic oiler has been successfully developed, especially suitable for the specific oiling requirements of YBF type motors for mine main ventilation fans (shaft extension end bearing and non-shaft extension end bearing). This product has obtained a Class I explosion-proof certificate, certificate number: CCRI22.1212, explosion-proof mark: Exdb ib IMb (explosion-proof and intrinsically safe type).

I. Product Model

| Serial Number | Name | Model | Description |

| 1 | Mine Fan Lubricating Grease Automatic Oiler | XCZLDZR-2.0H | Explosion-proof and intrinsically safe type with built-in heating function, capable of independent operation to complete oiling. Oil capacity: 2.0L. Explosion-proof mark: Exdb ib IMb (Standard) |

| 2 | Centralized Control System | XCZL-CM | Consists of a 15.6-inch touch all-in-one machine, control unit, and control software system, realizing centralized monitoring of all oilers (providing both wired and wireless networking methods, wireless effective distance 1000~2000 meters, choose one according to the on-site situation). Wireless effective distance 1000~2000 meters ,根据现场情况任选其一) (Optional) |

| 3 | Lightweight Grease Gun | SJB-10Z type | Easily complete oil replenishment for the automatic oiler by inserting the grease gun into a standard 15Kg barrel of lithium-based grease (one for four automatic oilers). (Standard) |

| 4 | Mobile Phone APP Monitoring System | XCZL-APP | Real-time monitoring via mobile phone APP (supports Android, HarmonyOS). (Optional) |

| 5 | Intelligent SMS Alarm Platform | XCZL-SMS | Real-time alarm information sent via Alibaba Cloud SMS platform. (Optional) |

XCZL–––Company code, D–––Electric, Z–––Automatic, R–––Grease, 2.0–––Oil capacity, H–––Heating type

II. Operating Parameters

| Input Voltage | Motor Power | Heating Power W/(m•K) | Maximum Operating Pressure | Pump Core Outlet Flow Rate | Operating Temperature | Lubricating Grease Model | Oil Capacity |

| AC 200V | 90W | ≤20W | 16M |

Front Shaft 6mL/M Rear Shaft 3mL/M |

-20℃ to 50℃ | 1#~3# | 2L |

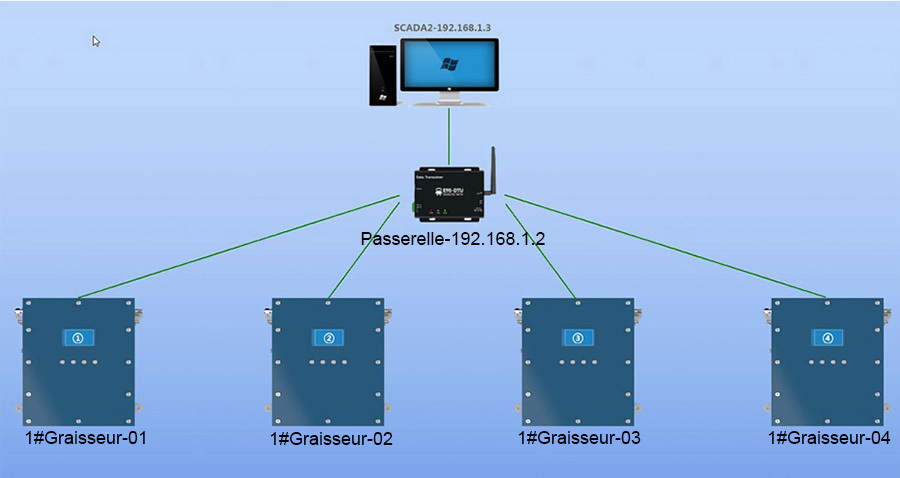

III. Automatic Oiling System Networking Method

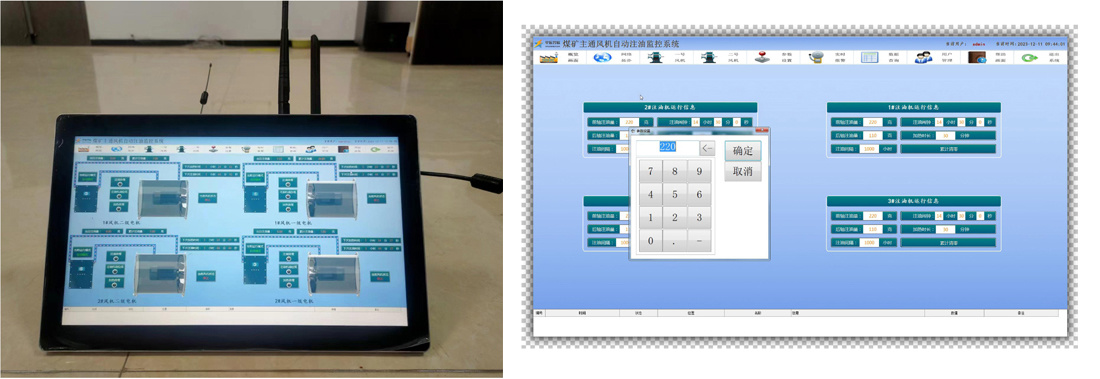

This system uses a wireless networking method. After powering on, it automatically connects to the centralized control computer, and the monitoring system can be used to monitor and set parameters for four oilers uniformly. (Note: The oiler has a built-in wireless networking and communication device connected to the centralized control computer.)

IV. Product Features

1. Independent Oiling: The automatic oiler consists of an oil pump assembly, controller unit, heating system, sensors, and LCD screen, forming a complete, independent intelligent oiling system. It does not require an additional control system and can simultaneously oil the front and rear shafts of the running motor, with on-site setting and real-time monitoring functions.

2. Pressure Alarm: Automatic alarm function when oil pipe leakage causes no oiling pressure or overpressure due to blockage.

3. High and Low Oil Level Alarm: High and low liquid level sensors can monitor the oil level in the oil pump in real time. When the oil level exceeds the maximum oil level or is below the minimum oil level the system will automatically issue an alarm to ensure normal operation of the oil pump.

4. Precise Oiling: Based on the oiling parameters indicated on the motor nameplate, the front and rear oil outlet oil output can be set through the system settings without any manual adjustment, realizing precise oiling.

5. Automatic Heating: The built-in temperature sensor automatically determines whether to start the heating function according to the ambient temperature, ensuring smooth oiling operation.

6. Intelligent Oiling: The start/stop sensor automatically detects whether the motor is running and only oils the running fan motor.

7. Easy Oil Replenishment: Each automatic oiler comes with a lightweight grease gun for convenient and quick oil replenishment.

8. Self-Protection Function: A one-way valve inside the oiler prevents backflow of oil from the lubricating pump; a plunger type pressure regulating valve (safety valve) controls the working pressure of the pump to protect the pump (if the system pressure is overloaded, the pressure oil is automatically returned to the tank through the pressure regulating valve).

9. Centralized Control System: The centralized intelligent control system consists of a 15.6-inch touch screen all-in-one machine, a control unit, and a control system. It can centrally monitor all oil injectors (providing both wired and wireless networking methods, choose one according to the customer's site environment). The wireless networking method has an effective transmission distance of 1000~2000 meters.

10. Rich Data Interfaces: Provides multiple data interface formats for easy data connection with other system platforms, such as the main ventilation fan online monitoring system. (Data server middleware, Modbus RTU protocol, direct database submission, etc.).

11. Intelligent Control Platform: Supports intelligent SMS alarm system platform and mobile phone APP system (Android, HarmonyOS), which can realize various alarm information SMS sending and real-time monitoring on the mobile phone end.

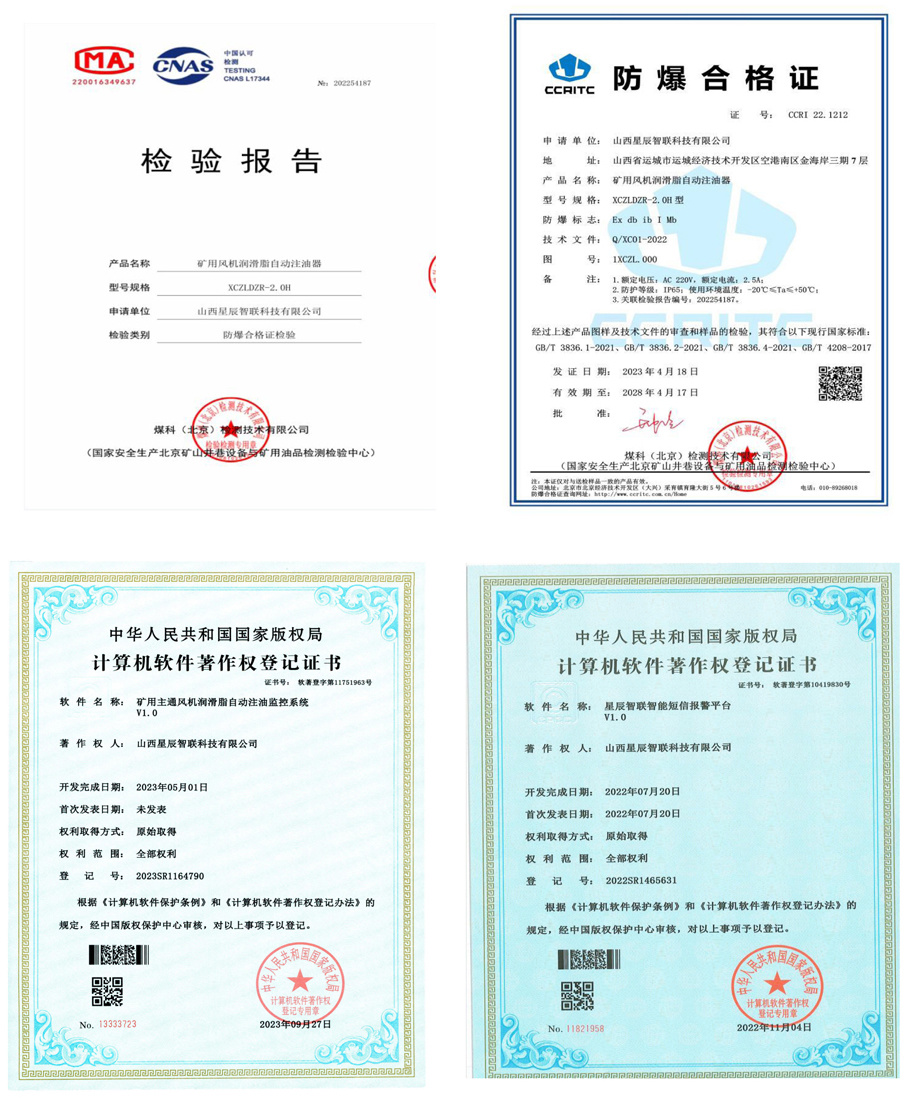

12. Safety Certification : Obtained Class I explosion-proof certificate, certificate number: CCRI22.1212 Explosion-proof mark: Exdb ib I Mb ( Explosion-proof and intrinsically safe )。

V. Installation and Function Setting

1. Working Principle

The XCZLDZR-2.0H automatic lubricating grease device consists of two parts: the oil injection pump assembly and the centralized control system. This automatic oil injector consists of an electric oil pump, an oil storage tank, a microcomputer controller, an LCD display panel, a pressure gauge, an oil outlet pipe, a pressure regulating valve, a heating belt, and other components. The lubricating pump uses a specially made disc-type motor, which drives the eccentric wheel to reciprocate the plunger through a gear reduction mechanism to complete the oil suction and discharge process. Its oil suction method uses a pressure oil pan vacuum oil suction, and the oil agent in the oil storage tank does not accumulate. This automatic oil injector has two oil outlets (front and rear axle oil outlets), one refueling port, and two heating belt outlets. Wrap the heating belt around the oil outlet pipe of the oil injection pump and fix it with aluminum foil tape. Connect it to the inlet pipes of the front and rear bearings of the motor through a three-way valve respectively. The other end of the three-way valve has a grease nozzle for manual refueling. Connect the oil outlet marked "front axle" to the front bearing of the motor, and the oil outlet marked "rear axle" to the rear bearing of the motor. Then fix the explosion-proof box on the main ventilation fan in an appropriate position. The operation parameters can be set in the following ways: (Set through the automatic oil injector's own setting operation function or through the centralized control system installed in the duty room).

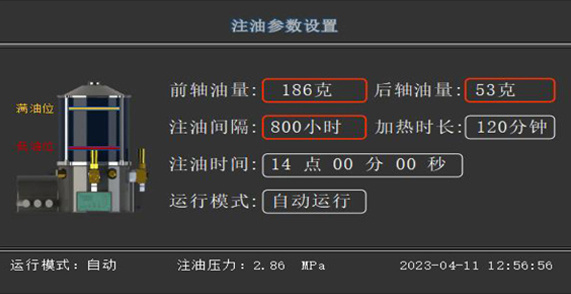

2. Main Functions of Automatic Oiler Setting :

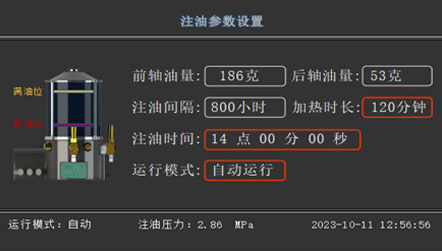

1) Oil Requirement Setting

Taking the motor model YBF-560S2-10 as an example, its rated power is 200kW. According to its nameplate marking, at a medium temperature of 40℃, every 800 hours, the oil requirements for the front and rear axles of the motor are 186g and 53g respectively. Just fill in the corresponding parameter information in the system setting window, and the oil injection pump will automatically calculate the daily oil requirement of the motor, without manual adjustment.

The automatic oiler uses lithium-based grease, model 1#-3#. It is recommended that northern users use 2# lithium-based grease in winter and 3# lithium-based grease in summer.

2) Oil Injection Time Setting

The system defaults to oil injection at 2 PM every day. Users can set the daily oil injection time according to their needs.

3) Heating Time Setting

In order to ensure that users in northern areas can successfully complete oil injection in winter, the system has a temperature sensor that can automatically start heating before the oil injection work begins according to the ambient temperature. The system defaults to a heating duration of 120 minutes.

4) Operation Mode

The modes are automatic and manual. The system defaults to automatic operation. When the parameter is set to manual mode, the manual oil injection work can be carried out using the button on the casing.

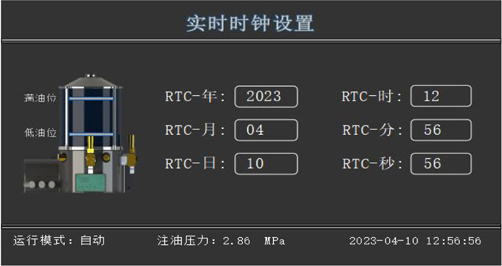

5) Clock Setting

Mainly for the time calibration and setting of the oil injector.

5) Oil Injector Display

The following figure shows the display interface during the operation of the oil injector, which includes all status information data: The oil injection and heating time is the start time of the next cycle. The front axle oil injection amount and the rear axle oil injection amount are the total oil injection amount of the two motors. The daily oil injection amount is the total amount of the front axle and rear axle. The cumulative oil injection is the cumulative total of all oil injection amounts of the current automatic oil injection pump. The running status information includes running, heating failure, overpressure, and other information prompts.

Fan Status: Displays the current running status (start and stop) of the fan motor.

Operation Mode: Automatic mode or manual mode.

Oil Injection Pressure: Displays the current pressure information of the oil injection pump.

Ambient Temperature: Displays the current ambient temperature of the oil injector to determine whether to automatically start heating.

If an oil level alarm occurs, the system will prompt with a "flashing" word, and the user should pay attention to refueling or draining operations to ensure that the oil injection work proceeds smoothly.

3. Centralized Control System Functions

The centralized control system consists of a 15.6-inch touch screen, a microcomputer controller, and control software. The intelligent control system is installed in a suitable location in the duty room (can be placed on the desk or hung on the wall), and an external 220V power supply is required.

1) Uniformly set the working parameters of each oil pump (oil injection start time, front and rear axle oil injection amount, heating time, etc.).

2) Real-time monitoring of the operation of each oiler. (Fan start/stop status, oiler operation mode (automatic mode, manual mode), daily oil injection amount (front axle oil injection amount and rear axle oil injection amount), cumulative oil injection amount, operation status, next oil injection and heating time, etc.).

3) Receive various alarm information (blockage or pipeline oil leakage alarm, heating abnormal alarm, high and low oil level alarm, etc.).

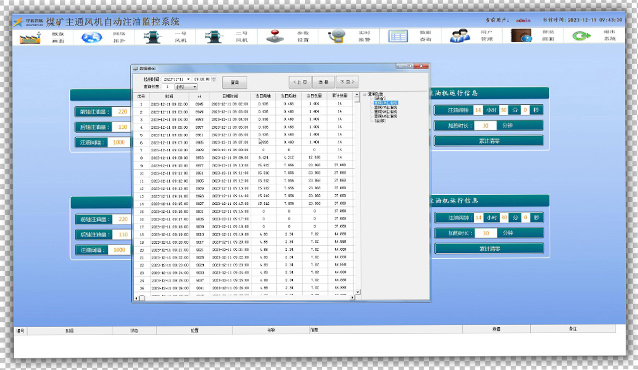

4) Data query (realize the query of detailed data and summary data reports of oil injection records of each oiler in any time period, as well as the alarm log query function).

4. Lightweight Grease Oil Gun

Features and Performance

• Suitable for adding oil to various thin oil and grease lubricating pumps.

• Insert the oil gun into a standard 15Kg barrel of lithium-based grease to operate.

• Portable, easy to operate, and versatile

• Equipped with a 1.5-meter hose and quick connector

• Medium used: 000-3# lithium-based grease, N22-N320 mechanical oil

• Ambient temperature: -20-80℃

• Nominal flow rate: 10mL/CY Nominal pressure: 4.0MPa

• Piping form: Hose with quick connector

Operating Instructions:

1. Insert the oil gun into the oil cylinder, remove the front quick connector nut, operate the oil gun to discharge the oil from the outlet, then insert it into the oil pump quick connector body, and operate the oil gun to add oil to the oil pump.

2. When the grease in the storage cylinder is added to the highest oil level (mark: H■OVER·FLOW■) or the system prompts an alarm, the oil gun should be operated slowly to add oil to the lubricating pump storage cylinder to avoid damaging the lubricating pump.

3. Exit: Push the quick connector nut forward to the bottom to exit.

5. Intelligent Control Platform

Utilizing internet-based, cloud platform, and stable and reliable middleware and database technologies, an intelligent integrated digital control platform is built. It provides users with convenient and fast mobile internet APP services. Users can control the working conditions of various oil injection pumps anytime and anywhere. The intelligent SMS platform service can push various alarm messages to the mobile phones of designated personnel via SMS.

By installing the APP system on your mobile phone, you can monitor the oil injection status anytime and anywhere, and it also provides functions such as historical oil injection data report query.

Based on Alibaba Cloud's SMS platform, alarm information can be pushed in real time to the mobile phones of designated personnel. It is possible to grasp various abnormal oil injection situations and troubleshoot them in time.

The intelligent SMS alarm platform sends various alarms to the mobile phones of designated personnel in the form of SMS messages.

V. Product Qualifications

The company's main business is the design, research and development, and manufacturing of various ventilators and their supporting products for mines, non-coal mines, and rail transit. Products involve 38 series of fan products, more than 3,000 specifications, including FB(D) series, FBC(D)Z series, FKZ series, rail transit SDS series, tunnel SDF series, etc.; supporting products include shaft, inclined shaft self-resetting explosion-proof doors, louver-type automatic regulating air doors, side-opening (vertical) automatic regulating air doors, butterfly valves, silencers, main ventilator online detection and fault diagnosis systems, non-stop fan reverse systems and intelligent oil injection systems, which can fully meet the ventilation needs of mines and are sold to various domestic fields and international markets such as Russia and Canada.

In recent years, the company has successively won the honorary titles of "Yuncheng Enterprise Technology Center", "Yuncheng Excellent Enterprise", "Yuncheng Intellectual Property Demonstration Enterprise", and "Innovative Small and Medium-sized Enterprise". The company has passed the "ISO9001 Quality Management System Certification", "ISO14001 Environmental Management System Certification", "ISO45001 Occupational Health and Safety Management System Certification", and its products have passed the "China National Compulsory Product Certification". It has also obtained a number of patents. With advanced process equipment, strong technical strength, excellent product quality, and a perfect service system, it has won unanimous recognition and praise from users. In particular, the green, environmentally friendly, and low-noise fans that have been focused on the market in recent years have achieved rapid development, becoming a well-known enterprise in the fan industry with leading technology.

Previous Page:

Product Inquiry

*Please leave your phone number, we will contact you within 24 hours!